7 Essential Tips for Choosing the Right Air Circuit Breaker for Your Electrical Systems

In today's rapidly evolving electrical infrastructure, the selection of appropriate protection devices is paramount, particularly the air circuit breaker (ACB), which plays a crucial role in safeguarding electrical systems and ensuring reliable operation. According to the International Electrotechnical Commission (IEC), ACBs are designed to disconnect electrical circuits to prevent damage from overloads, short circuits, and faults, thereby enhancing safety and efficiency. Moreover, the global market for air circuit breakers is projected to grow significantly, with a CAGR of 5.8% from 2021 to 2026, as reported by Research and Markets. This emphasizes the need for industry professionals to thoroughly understand the operational specifications and applications of ACBs, enabling them to make informed decisions in selecting the right circuit breakers that align with their system requirements and safety standards.

Factors to Consider When Selecting Air Circuit Breakers

When selecting the right air circuit breaker (ACB) for your electrical systems, several key factors must be considered to ensure optimal performance and safety. First, it is essential to evaluate the current and voltage ratings of the ACB, as it needs to match the specific requirements of your system. This ensures that the breaker can handle the expected electrical load without tripping unnecessarily. Additionally, understanding the fault levels within the electrical system will help in choosing a circuit breaker that can withstand potential short-circuits and overloads.

Another important consideration is the type of environment where the ACB will be installed. Factors such as ambient temperature, humidity, and potential exposure to corrosive elements can significantly impact the durability and reliability of the circuit breaker. For instance, applications in marine or industrial environments may require specially designed ACBs that offer enhanced protection against harsh conditions. Furthermore, assessing the features of various ACBs, such as the availability of intelligent monitoring and communication capabilities, can lead to improved system management and enhanced safety measures.

Understanding the Different Types of Air Circuit Breakers

When selecting the right air circuit breaker (ACB) for your electrical systems, it's crucial to understand the different types available. Air circuit breakers are designed to protect electrical circuits from overloads and short circuits, and they are available in several configurations, including plain break and magnetic break types. The plain break ACBs operate using a mechanical mechanism to separate contacts, effectively interrupting current flow. In contrast, magnetic break ACBs use the electromagnetic forces to achieve a faster and more reliable disconnection during fault conditions.

Another important category is the necessary current rating of the ACBs, which can range from low to high voltages. Low-voltage ACBs are typically used in residential and light commercial applications, while medium and high-voltage ACBs serve industrial and utility environments. Additionally, ACBs can be classified based on their operating mechanisms, such as the hydraulic mechanism, which provides a time-delay feature, and the electronic mechanism, offering programmable settings for enhanced protection. Understanding these distinctions will guide you in choosing the most suitable air circuit breaker for your specific electrical system requirements.

Key Performance Specifications for Air Circuit Breakers

When selecting the right air circuit breaker (ACB) for your electrical systems, it is essential to consider key performance specifications that can significantly impact reliability and efficiency. One of the most critical specifications is the current rating, which defines the maximum load the breaker can handle without tripping. Choosing a breaker with the appropriate rating ensures that your system operates smoothly, minimizing the risk of overloads that could lead to failures or downtime.

Another important specification to examine is the breaking capacity, which indicates the ability of the ACB to interrupt current under fault conditions. A high breaking capacity is essential for protecting circuits from short-circuits or ground faults. Additionally, consider the operational characteristics of the breaker, such as the type of tripping mechanism, to ensure it aligns with your system's requirements. These performance specifications are vital when making a decision, as they contribute to the overall safety and effectiveness of your electrical infrastructure.

7 Essential Tips for Choosing the Right Air Circuit Breaker for Your Electrical Systems - Key Performance Specifications for Air Circuit Breakers

| Specification | Description | Importance |

|---|---|---|

| Rated Current | The maximum continuous current the breaker can handle without tripping. | Ensures the breaker can handle the expected load. |

| Breaking Capacity | The maximum fault current that the breaker can interrupt without failure. | Critical for protection against short circuits. |

| Voltage Rating | The maximum voltage the ACB is designed to operate at. | Ensures compatibility with the electrical system. |

| Trip Settings | Adjustable settings that determine at what current the breaker will trip. | Allows customization to specific protection needs. |

| Auxiliary Contacts | Additional contacts used for signaling or control functions. | Enhances functionality and monitoring of the system. |

| Size and Weight | Physical dimensions and weight of the breaker. | Important for fitting into existing panels and structures. |

| Standards Compliance | Conformity to specific safety and performance standards. | Ensures reliability and safety of the circuit breaker. |

Safety Features to Look for in Air Circuit Breakers

When selecting an air circuit breaker (ACB) for your electrical systems, prioritizing safety features is paramount. According to the International Electrotechnical Commission (IEC), around 30% of electrical equipment failures are linked to inadequate protection mechanisms. Therefore, it’s crucial to choose ACBs equipped with advanced safety characteristics. One such feature is the overload protection, which ensures that the circuit breaker can automatically shut off power in case of an overload, thereby preventing potential damage or fires. This feature is often accompanied by short-circuit protection that interrupts the circuit quickly during fault conditions.

Another essential safety aspect is the arc extinction technology used within the ACB. A report from the IEEE indicates that effective arc quenching mechanisms can reduce electrical hazards significantly. Look for ACBs with vacuum or air chute arc extinguishing techniques, which not only improve reliability but also enhance operational safety. Furthermore, certain models offer ground fault protection, a vital feature that detects abnormal currents and safeguards both equipment and personnel. Investing in air circuit breakers with these safety enhancements not only complies with safety standards but also fosters a secure operational environment.

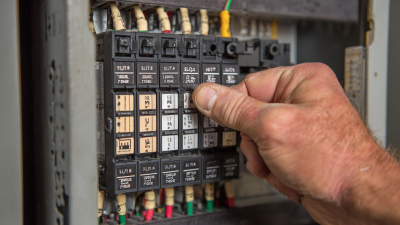

Installation and Maintenance Guidelines for Air Circuit Breakers

When selecting and maintaining air circuit breakers (ACBs) for electrical systems, understanding installation and maintenance guidelines is critical to ensuring safety and performance. According to the International Electrotechnical Commission (IEC), proper installation can enhance the lifespan of ACBs by up to 20%. Key installation factors include ensuring that the circuit breakers are installed in a clean, dry environment to prevent dust and moisture from impairing their operation. Additionally, installers should ensure that ACBs are properly aligned with the electrical panel to avoid mechanical stresses which can lead to premature failures.

Regular maintenance is equally essential. The National Fire Protection Association (NFPA) recommends conducting a routine maintenance inspection every six months to check for signs of wear and tear, overheating, and mechanical functions. Preventive maintenance measures such as tightening connections, checking insulation resistance, and testing trip functions can greatly reduce the risk of electrical failures. In fact, data from the Electrical Safety Foundation International (ESFI) states that well-maintained ACBs can reduce downtime by approximately 15%, ultimately saving costs associated with unexpected outages and equipment repairs. A proactive approach to installation and maintenance not only enhances system reliability but also ensures compliance with safety standards.

Related Posts

-

Understanding the Challenges of Miniature Circuit Breakers in Modern Electrical Systems

-

9 Essential Tips for Choosing the Right Home Circuit Breaker

-

A Comprehensive Guide to Understanding Molded Case Circuit Breakers in Industrial Applications

-

Ultimate Guide to ACB Breaker Selection and Maintenance for Optimal Performance

-

7 Facts You Didn't Know About ACB Breakers: The Best Choices for Your Electrical Needs

-

How to Select the Best Surge Protection Solutions for Your Business Needs