Ultimate Guide to ACB Breaker Selection and Maintenance for Optimal Performance

In today's ever-evolving electrical landscape, the selection and maintenance of ACB breakers (Air Circuit Breakers) play a crucial role in ensuring optimal performance and reliability. According to the International Electrotechnical Commission, improper circuit breaker selection can lead to efficiency losses of up to 30% in industrial systems. Furthermore, a report by the National Fire Protection Association highlights that over 40% of electrical failures are linked to inadequate maintenance practices. This underscores the importance of not only selecting the right ACB breaker for your application but also implementing a robust maintenance regime to prolong its lifespan and maintain operational safety. As we delve into the ultimate guide to ACB breaker selection and maintenance, we will explore key considerations and best practices that will empower engineers and technicians to make informed decisions, safeguard their systems, and optimize power performance in any environment.

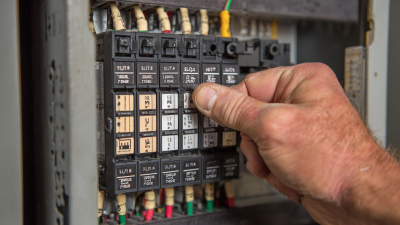

ACB Breaker Selection: Key Factors to Consider for Optimal Performance

When selecting an Air Circuit Breaker (ACB), it's essential to consider several key factors that significantly influence performance and reliability. First and foremost, understanding the load characteristics of your electrical system is critical. This involves assessing the maximum load current and any potential inrush currents that may occur during startup. Properly sizing the ACB ensures that it can handle these demands without tripping unnecessarily, which can lead to operational disruptions.

Another important factor to consider is the environment in which the ACB will be installed. Factors such as temperature, humidity, and the presence of corrosive elements can affect the breaker's performance and lifespan. Choosing an ACB with the appropriate IP rating can provide protection against dust and moisture, ensuring optimal functioning over time. Additionally, understanding the maintenance requirements and the availability of spare parts is crucial for ensuring long-term reliability of the breaker, allowing for timely interventions and reducing the risk of unexpected failures.

Understanding Different Types of ACB Breakers: A Comparative Overview

When it comes to circuit protection, ACB (Air Circuit Breakers) are essential for providing reliable and efficient performance. Understanding the different types of ACB breakers can help you choose the right model for your specific needs. The primary classifications include standard ACBs, digital ACBs, and intelligent ACBs. Standard ACBs are the most widely used and offer basic protection against overloads and short circuits. They are ideal for industrial settings where simplicity and reliability are crucial.

In contrast, digital ACBs incorporate advanced features such as adjustable settings and remote monitoring capabilities. These breakers allow for greater flexibility in managing power distribution systems, making them suitable for facilities that require precise control and data analysis. Lastly, intelligent ACBs take it a step further by integrating with smart grid technologies, providing real-time data and enhanced communication capabilities. This type of ACB is particularly beneficial for modern infrastructures aiming to optimize energy efficiency and reliability while minimizing downtime.

By comparing these various types of ACB breakers, you can better assess your operational requirements and make informed decisions. Each type offers unique advantages that cater to different applications, ensuring that you can maintain optimal performance in your electrical systems.

Top Tips for ACB Breaker Maintenance to Enhance Longevity

In the realm of electrical systems, the maintenance of Air Circuit Breakers (ACBs) is crucial to ensure optimal performance and longevity. According to a report by the International Electrotechnical Commission, regular maintenance can enhance the lifespan of ACBs by up to 30%. Routine inspections should focus on the mechanical and electrical components, ensuring that all moving parts are lubricated and that contacts are clean. It’s recommended to perform these inspections at least bi-annually to prevent unexpected failures that could disrupt operations.

Moreover, the use of thermal imaging technology has proven highly effective in identifying potential issues before they escalate, such as loose connections or overheating components. The Electrical Power Research Institute has indicated that implementing predictive maintenance strategies, including thermal imaging, can reduce unplanned outages by 75%. By adopting a proactive approach to ACB maintenance, organizations can not only improve reliability but also extend the overall operational lifespan of their equipment, leading to significant cost savings and improved safety in electrical systems.

Common ACB Breaker Issues and How to Troubleshoot Them Effectively

When it comes to ACB (Air Circuit Breaker) performance, understanding common issues and effective troubleshooting techniques is crucial for maintaining optimal functionality. According to industry reports, around 30% of electrical faults can be traced back to ACB failures, signaling the need for preventive maintenance and rapid diagnostics. Typical problems include tripped breakers, poor insulation, and overheating, which can not only lead to equipment damage but also pose serious safety risks.

To troubleshoot these issues effectively, regular inspections and testing are recommended. For instance, thermographic scanning can identify hot spots that may indicate overloaded circuits or failing components. Additionally, regular cleaning and tightening of connections can prevent the accumulation of dust and corrosion, which are known causes of electrical failures. Moreover, the implementation of predictive maintenance strategies, where data analytics is used to anticipate equipment failures before they occur, can significantly enhance performance and reliability. By prioritizing these practices, facilities can minimize downtime and ensure ACB systems operate at their best.

Best Practices for Testing and Monitoring ACB Breaker Performance

When it comes to ensuring the optimal performance of Air Circuit Breakers (ACBs), regular testing and monitoring are crucial components that cannot be overlooked. A systematic approach to testing ACBs includes both functionality assessments and thermal imaging. Conducting routine functional tests helps identify any anomalies in the breaker’s operation, while thermal imaging can pinpoint hotspots that may indicate a fault or impending failure. Implementing these practices not only prolongs the lifespan of the breakers but also enhances the safety and reliability of the entire electrical system.

Monitoring ACB performance regularly involves a combination of visual inspections and advanced diagnostic tools. Visual inspections should focus on signs of wear, corrosion, and any loose connections that could impact performance. Furthermore, integrating smart monitoring solutions, like real-time condition monitoring systems, allows for immediate analysis of operational data. These tools can provide insights into parameters such as load levels and fault currents, facilitating proactive maintenance decisions. By adopting these best practices, organizations can ensure their ACBs operate efficiently, minimizing downtime and optimizing overall system performance.

Related Posts

-

Understanding the Challenges of Miniature Circuit Breakers in Modern Electrical Systems

-

9 Essential Tips for Choosing the Right Home Circuit Breaker

-

A Comprehensive Guide to Understanding Molded Case Circuit Breakers in Industrial Applications

-

Understanding Challenges Faced with Electric Breaker Switches in Modern Applications

-

Innovative Usage Scenarios of DC Molded Case Circuit Breakers in Modern Electrical Systems

-

7 Essential Tips for Choosing the Right Electric Breaker for Your Needs