Top Vacuum Circuit Breaker Types You Should Know About?

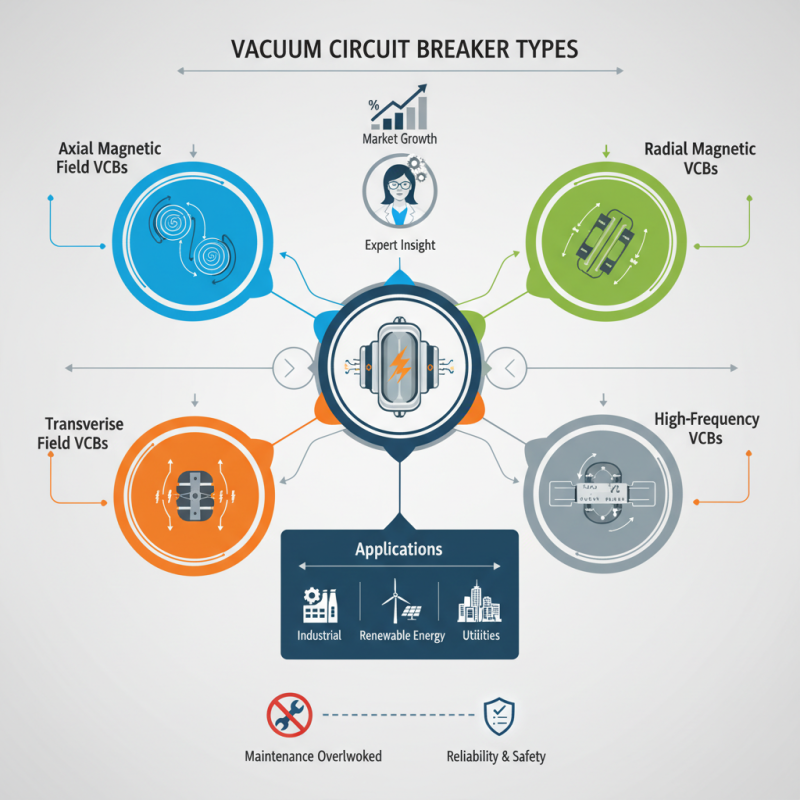

Vacuum circuit breakers (VCBs) play a crucial role in modern electrical systems. They offer reliable protection for high-voltage applications. According to a recent report by ResearchAndMarkets, the global vacuum circuit breaker market is expected to grow at a CAGR of 7.8% from 2021 to 2026. This growth highlights the increasing adoption of VCBs across various industries.

Dr. Emma Zhao, a leading expert in electrical engineering, states, "Vacuum circuit breakers are essential for ensuring operational efficiency and safety." This underscores the importance of understanding different VCB types available. Each type has unique characteristics that suit various applications.

While VCBs are praised for their effectiveness, they are not without challenges. The need for proper maintenance is often overlooked. Operators must ensure that devices operate optimally. Understanding the nuances of VCBs can significantly impact reliability and safety in electrical systems.

Overview of Vacuum Circuit Breakers and Their Importance

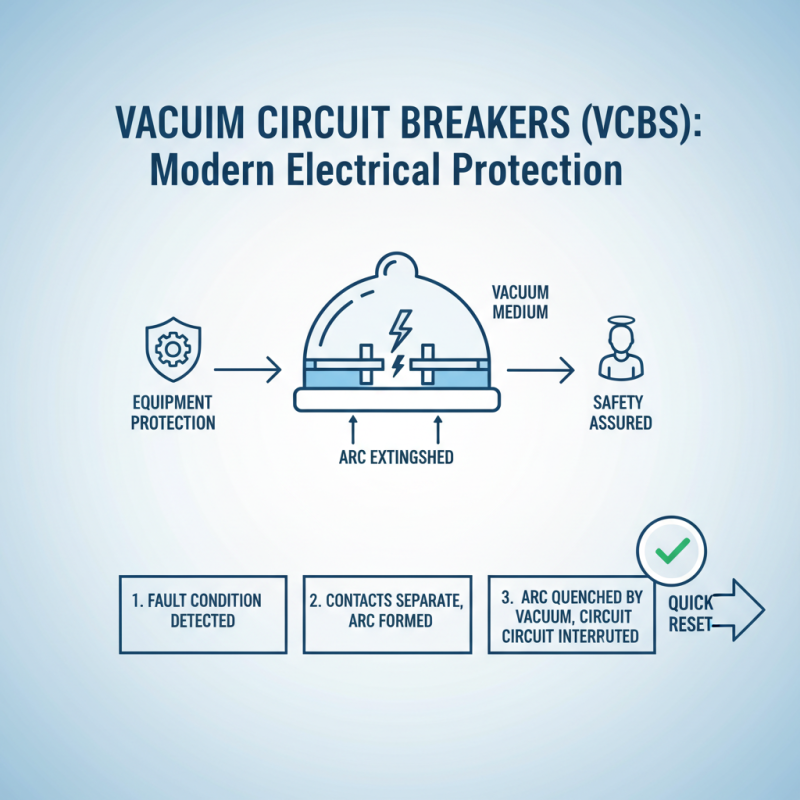

Vacuum Circuit Breakers (VCBs) play a crucial role in modern electrical systems. They are designed to interrupt the circuit under fault conditions. This quick action prevents damage to equipment and ensures safety. The key feature of VCBs is their use of vacuum as the interrupting medium. When the contacts separate, an arc is formed. This arc is quickly extinguished due to the vacuum environment, allowing the breaker to reset without delay.

The importance of VCBs cannot be overstated. They are compact, reliable, and require minimal maintenance. Their durability makes them suitable for a variety of applications, including industrial and commercial environments. However, VCBs are not without challenges. Proper installation and regular inspection are necessary to ensure optimal performance. Over time, wear and tear can affect their operation. It's vital to address these concerns proactively.

In conclusion, recognizing the value of Vacuum Circuit Breakers aids in safeguarding electrical systems. A deeper understanding of their functions and limitations can lead to better choices in system design and operations. While VCBs are beneficial, being aware of their maintenance needs helps in preventing unforeseen failures.

Different Types of Vacuum Circuit Breakers and Their Applications

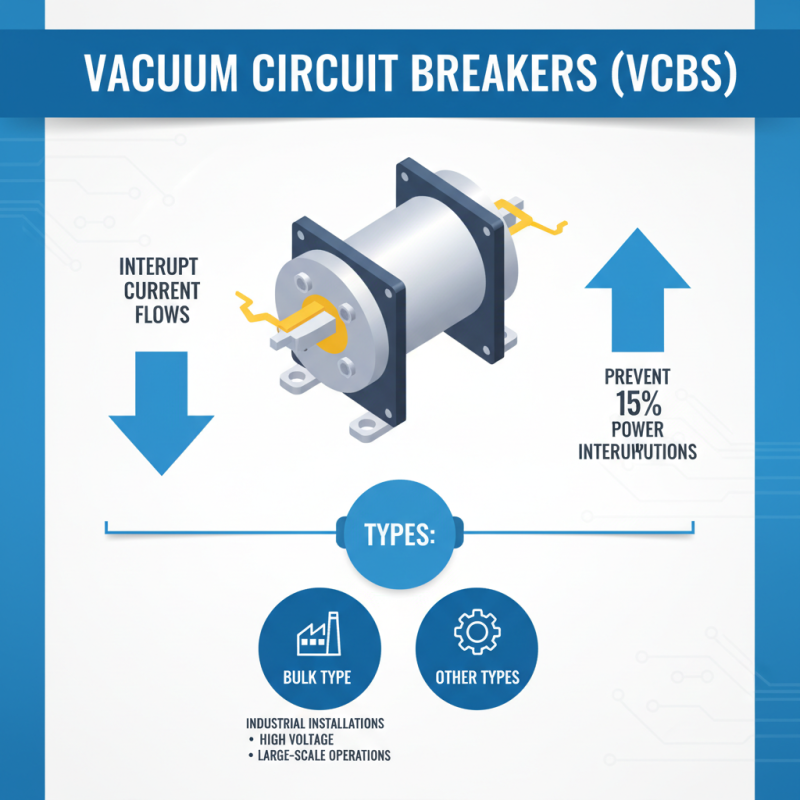

Vacuum circuit breakers (VCBs) play a crucial role in electrical systems. They effectively interrupt current flows. Various types of VCBs exist, each catering to specific applications. For instance, the bulk type is widely used in industrial installations. With the ability to handle high voltages, it is reliable for large-scale operations. Data indicates that around 15% of power interruptions are due to faults that VCBs can address.

Another type is the immersion type VCB. This version is designed for environments with limited space. It offers flexible installation options. They are typically found in urban electrical systems, where space is a premium. According to industry reports, this type has increased in demand by 20% over the last five years. Their utility in confined areas continues to grow.

However, some challenges exist. Maintenance can be complicated and costly. Additionally, not all VCBs are suitable for every application. Engineers must consider environmental factors. They must also evaluate the load requirements carefully. Misapplication of a VCB can lead to failures. It is essential to understand the nuances of each type.

Key Features and Advantages of Vacuum Circuit Breakers

Vacuum circuit breakers (VCBs) are crucial in modern electrical systems. They operate by isolating electrical faults in a vacuum environment, which prevents arc formation. This design offers several key features. For instance, VCBs can provide a longer lifespan. According to industry reports, they can last over 10,000 operations, significantly reducing maintenance costs.

One major advantage of vacuum circuit breakers is their compact size. They can be installed in smaller spaces compared to traditional breakers. The reduced footprint is an essential factor for many urban installations. Additionally, VCBs are highly efficient. They exhibit high dielectric strength, which enhances performance during overload conditions. Data indicates a decline in energy loss by 30% when using VCBs.

Despite their benefits, vacuum circuit breakers have limitations. They may not perform optimally in extreme temperatures. Furthermore, the initial investment can be higher than other types. Potential users should weigh these challenges against the long-term savings and reliability offered by VCBs. As the industry evolves, understanding these factors will guide decisions in electrical infrastructure.

Factors to Consider When Selecting a Vacuum Circuit Breaker

When selecting a vacuum circuit breaker, several factors come into play.

System voltage is critical. Ensure it matches the application's requirements.

Breakers operate differently at various voltage levels. The interrupting capacity matters too.

It refers to the maximum current a breaker can safely interrupt without failure. This ensures safety during faults.

Another key aspect is maintenance needs. Some vacuum circuit breakers require

frequent inspections, while others are more robust. Choosing one that aligns with your maintenance schedule can save time and resources.

Additionally, consider the environmental conditions. Extreme temperatures or

humidity levels can affect performance.

Size and weight are also crucial. Larger breakers can be difficult to install in tight spaces.

Compatibility with existing systems should not be overlooked. Confirm that the new breaker integrates smoothly with current operations.

It might sound straightforward, but many overlook these aspects in their selection process.

Ensure the breaker fits all practical aspects before making a final choice.

Maintenance Practices for Optimal Performance of Vacuum Circuit Breakers

Vacuum circuit breakers (VCBs) are integral to maintaining electrical systems' reliability. For optimal performance, regular maintenance is crucial. Begin with visual inspections. Look for any signs of wear or damage on components. Dust and debris can accumulate, affecting functionality. Keeping components clean can prevent failures during operation.

Testing the circuit breaker on a schedule is vital. Check the insulation resistance regularly. This helps ensure that the VCB functions correctly under load. It's easy to overlook this step, but failure to test may lead to unexpected breakdowns. An unexpected trip can disrupt power supply significantly.

It’s also wise to review operating mechanisms. Lubrication is necessary for smooth operation. But too much can attract dust. Finding the right balance is key. Additionally, end-users should keep an eye on tripping settings. Accidental adjustments can lead to inefficiencies. Regular training for personnel can improve awareness about common maintenance issues. These small practices contribute significantly to the longevity of vacuum circuit breakers.

Related Posts

-

Understanding the Key Differences Between Types of Vacuum Circuit Breaker Technologies

-

Top 10 Surge Protective Devices for Home and Office Use to Ensure Your Electronics Safety

-

How to Choose the Best Electric Breaker for Your Home and Business Needs

-

Ultimate Guide to Understanding Motor Protection Solutions for Industrial Applications

-

Understanding the Importance of Motor Protection Relay in Electrical Safety Systems

-

Exploring Market Trends for Switch Disconnectors at the 138th Canton Fair 2025 in China