What is a Power Circuit Breaker and How Does It Work in Electrical Systems

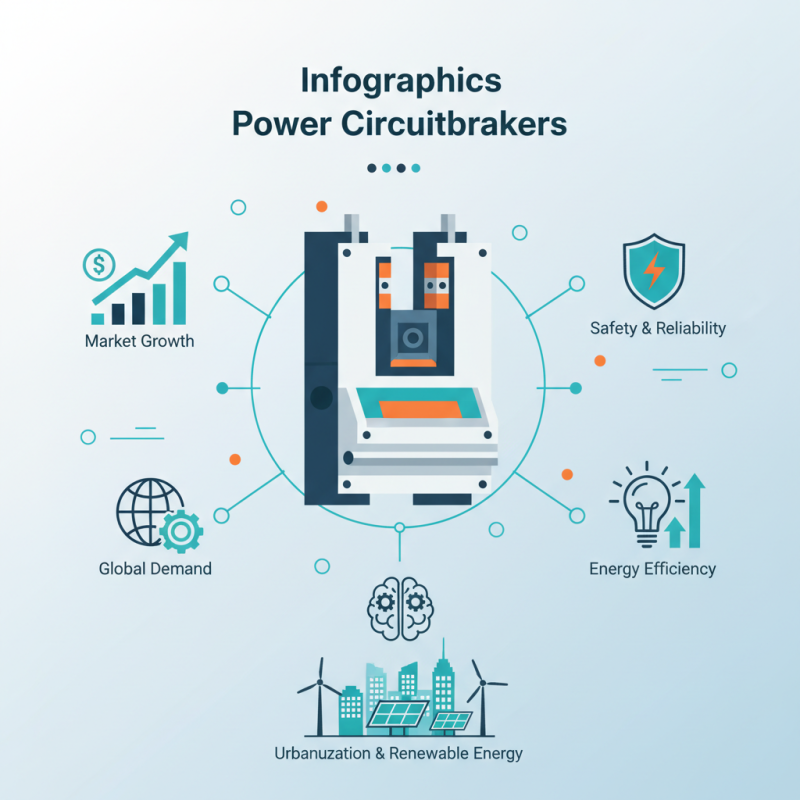

In modern electrical systems, the role of a power circuit breaker is pivotal for ensuring safety and reliability. According to a recent report by the International Electrotechnical Commission (IEC), the global market for power circuit breakers is projected to reach over $8 billion by 2025, driven by the increasing demand for energy efficiency and safety in electrical installations. These devices not only protect electrical circuits from overloads and short circuits but also contribute significantly to the overall stability of power distribution networks.

John Smith, a recognized expert in electrical engineering and author of "Advancements in Circuit Protection," emphasizes the critical importance of power circuit breakers: "Without these essential devices, we risk catastrophic failures and significant financial losses in our electrical infrastructure." Smith's insights underline the necessity for continuous innovation in power circuit breaker technology to meet the evolving challenges posed by urbanization and the expansion of renewable energy sources. As we explore the mechanisms and functions of power circuit breakers, it is essential to understand their contribution to safeguarding both industrial and residential electrical systems.

What is a Power Circuit Breaker?

A power circuit breaker is a critical component in electrical systems, designed to automatically interrupt electrical flow in the event of an overload or fault condition. This device protects electrical circuits from damage caused by excess current, ensuring both safety and reliability in power distribution. Power circuit breakers detect fault conditions by monitoring the current flowing through the circuit. When the current exceeds safe limits, the breaker trips, disconnecting the power supply to prevent overheating or potential fires.

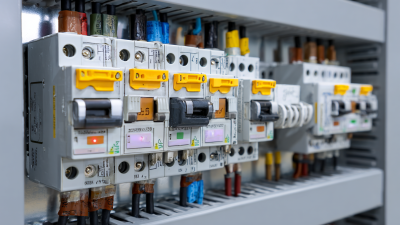

In addition to their protective function, power circuit breakers also provide a means for manual operation and maintenance. They can be easily reset once the fault has been resolved, allowing for quick restoration of power. These devices come in various configurations, including air-insulated, gas-insulated, and oil-insulated types, each suited for different environments and applications. The choice of breaker will depend on factors such as voltage levels, load requirements, and installation conditions, highlighting their versatility in electrical engineering.

Key Components of Power Circuit Breakers

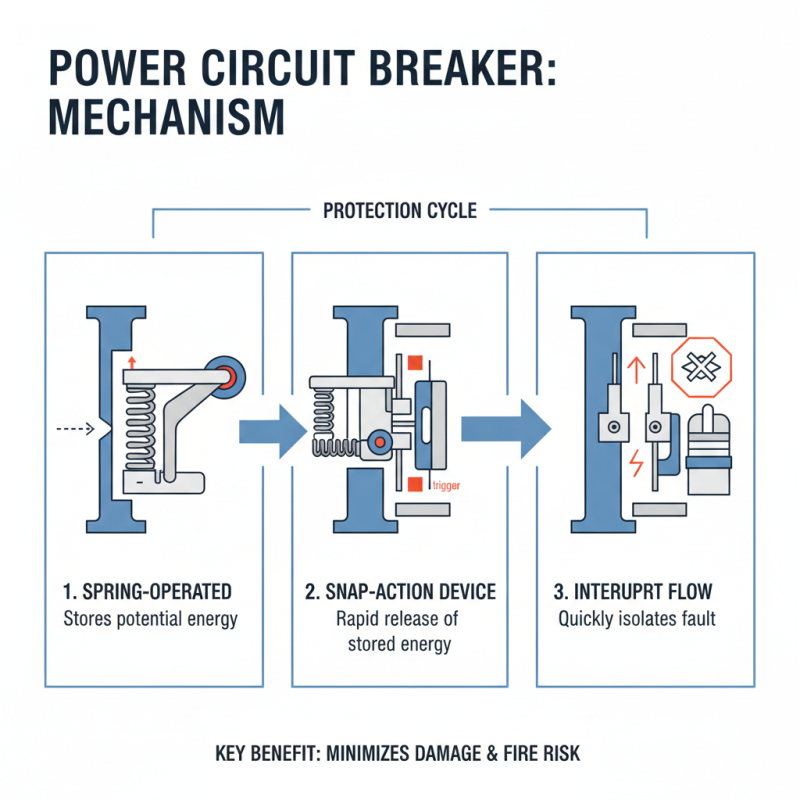

Power circuit breakers are crucial components in electrical systems, designed to protect electrical circuits from overloads and short circuits. Several key components contribute to the effective functioning of power circuit breakers. The first is the mechanism, which includes a spring-operated, snap-action device. This mechanism ensures that the circuit breaker can quickly interrupt the electrical flow in the event of a fault, minimizing potential damage to electrical equipment and reducing the risk of fire.

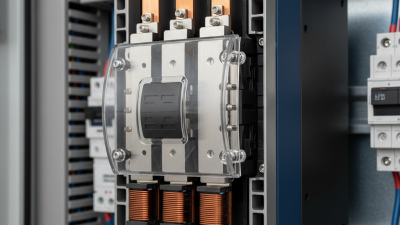

Another essential component is the contacts, typically made of a conductive material designed to safely handle high-current operations. The performance and durability of these contacts directly impact the reliability of the circuit breaker. According to a recent industry report, the lifespan of a power circuit breaker can range from 10,000 to 20,000 operations, depending on the design and quality of materials used. Additionally, the arc extinguishing system, which may involve air or gas, plays a vital role in dissipating the heat and energy generated during a fault, ensuring swift interruption without causing arcs that can damage the equipment.

Finally, electronic controls have become increasingly important in modern power circuit breakers, allowing for enhanced monitoring and protection capabilities. These controls can provide advanced features such as ground fault detection, overcurrent protection, and real-time diagnostics. The integration of these technologies is projected to grow, with the market for intelligent circuit breakers expected to reach $5 billion by 2025, highlighting the importance of continual advancements in design and functionality within electrical systems.

How Power Circuit Breakers Function in Electrical Systems

Power circuit breakers play a crucial role in the electrical systems of various industries, ensuring both protection and reliability. These devices are designed to interrupt current flow in the event of an overload or short circuit, thereby preventing damage to electrical equipment and the risk of fire. According to a report by Global Industry Analysts, the global market for circuit breakers is projected to reach $20.3 billion by 2027, underlining their importance in maintaining electrical safety and efficiency.

The operation of power circuit breakers centers on an electromechanical mechanism that detects faults through sensors and triggers the interruption swiftly. When a fault condition is identified, the circuit breaker opens its contacts, halting the current flow. This process is often enhanced by advancements in digital technology, which provide faster response times and improved monitoring capabilities. A study from the Electric Power Research Institute (EPRI) indicates that modern circuit breakers can reduce outage times by up to 50% compared to older models, significantly increasing the resilience of electrical grids.

In addition to their protective function, power circuit breakers facilitate the management and distribution of electrical load, which is essential in preventing system overloads and ensuring operational efficiency. The integration of smart technologies allows for real-time monitoring and remote operation, contributing to the overall performance of electrical networks. As energy consumption patterns continue to evolve, the role of power circuit breakers in electrical infrastructure design becomes increasingly pivotal, emphasizing the need for ongoing innovation and investment in these critical components.

Applications of Power Circuit Breakers in Industry

Power circuit breakers play a crucial role in various industrial applications by ensuring the safety and reliability of electrical systems. In manufacturing environments, these devices protect electrical equipment from overloads and short circuits that can cause significant damage or downtime. By rapidly interrupting electrical flow when a fault is detected, power circuit breakers help maintain operational continuity and prevent catastrophic failures that could disrupt production processes.

In addition to manufacturing, power circuit breakers are integral in energy distribution systems within industrial sectors. They help manage electrical loads by balancing supply and demand, which is essential for optimizing energy efficiency. Additionally, these breakers enable safe isolation of equipment for maintenance without risking the entire system's integrity. Their ability to operate at different voltage ratings makes them versatile tools that can be employed in various applications, including renewable energy systems and large-scale industrial plants, where continuous and reliable power is paramount.

Importance of Maintenance and Testing for Circuit Breakers

Proper maintenance and testing of circuit breakers are crucial for ensuring the reliability and safety of electrical systems. According to the National Fire Protection Association (NFPA), electrical failures account for approximately 13% of all reported fires in the United States, emphasizing the significance of well-maintained circuit breakers. Routine inspections and testing can identify potential issues before they escalate into catastrophic failures, leading to costly downtime and repairs. It is estimated that up to 70% of electrical failures could be prevented with effective maintenance protocols.

In addition to fire prevention, regular maintenance contributes to the longevity of circuit breakers. The International Electrotechnical Commission (IEC) states that circuit breakers have a lifespan of approximately 20-30 years, but this can be significantly impacted by environmental factors and usage patterns. Implementing standardized testing methods, such as insulation resistance and contact resistance testing, can help ensure that circuit breakers perform efficiently throughout their lifecycle. Furthermore, data from the Electrical Safety Foundation International (ESFI) highlight that a proactive maintenance strategy can reduce the likelihood of equipment failure by up to 40%, underscoring the importance of routine checks and timely repairs.

Related Posts

-

7 Essential Tips for Choosing the Right Electric Breaker for Your Needs

-

What is the Function of a DC Molded Case Circuit Breaker

-

Common Issues with Electric Breakers: A Global Purchasing Insight

-

How to Choose the Best Electric Breaker for Your Home and Business Needs

-

Understanding Power Circuit Breakers: The Key to Safe Electrical Systems

-

How to Choose the Right Air Circuit Breaker for Your Electrical System