Understanding the Importance of Motor Protection Relay in Electrical Safety Systems

In modern electrical safety systems, the pivotal role of the motor protection relay cannot be overstated. As reported by the International Electrotechnical Commission (IEC), motor failures due to electrical faults account for nearly 30% of all industrial equipment downtime, leading to substantial financial losses. The implementation of a motor protection relay serves as a critical safeguard, ensuring that motor operations remain within their designated parameters, thus mitigating potential damage from overloads, short circuits, and phase failures.

Experts in the field, such as Dr. Henry Marshall, a renowned electrical engineer and author of "Electrical Protection Systems", emphasize the significance of this technology: “The motor protection relay is the unsung hero of electrical safety – it not only protects the equipment, but also enhances overall operational efficiency.” By detecting abnormal conditions and disconnecting the motor from the supply when necessary, these relays contribute significantly to the longevity of machinery and the safety of personnel during operation.

As industries continue to prioritize operational safety and reliability, understanding the functionality and importance of motor protection relays becomes essential. Not only do they play a vital role in maintaining system integrity, but they also support compliance with safety standards that protect both the workforce and equipment investment.

The Role of Motor Protection Relays in Preventing Electrical Failures

Motor protection relays are vital components in electrical safety systems, serving as the first line of defense against electrical failures. According to the International Electrotechnical Commission (IEC), improper motor protection can lead to significant downtime, with estimated costs reaching up to $1 million per hour in industrial settings due to equipment failure. These relays monitor various parameters such as overcurrent, undervoltage, and temperature, activating protective measures immediately when abnormalities are detected. This swift response can prevent catastrophic failures, prolonging the lifespan of motors and associated equipment.

Motor protection relays are vital components in electrical safety systems, serving as the first line of defense against electrical failures. According to the International Electrotechnical Commission (IEC), improper motor protection can lead to significant downtime, with estimated costs reaching up to $1 million per hour in industrial settings due to equipment failure. These relays monitor various parameters such as overcurrent, undervoltage, and temperature, activating protective measures immediately when abnormalities are detected. This swift response can prevent catastrophic failures, prolonging the lifespan of motors and associated equipment.

Moreover, a report by the Institute of Electrical and Electronics Engineers (IEEE) emphasizes that incorporating advanced motor protection relays can reduce the likelihood of electrical faults by up to 30%. By employing features such as programmable settings and real-time diagnostics, these relays not only safeguard against sudden electrical incidents but also facilitate routine maintenance and operational efficiency. The role of motor protection relays hence extends beyond mere protection; it embodies a proactive approach to electrical safety that is essential in maintaining the integrity and reliability of industrial operations.

Key Features of Effective Motor Protection Relay Systems

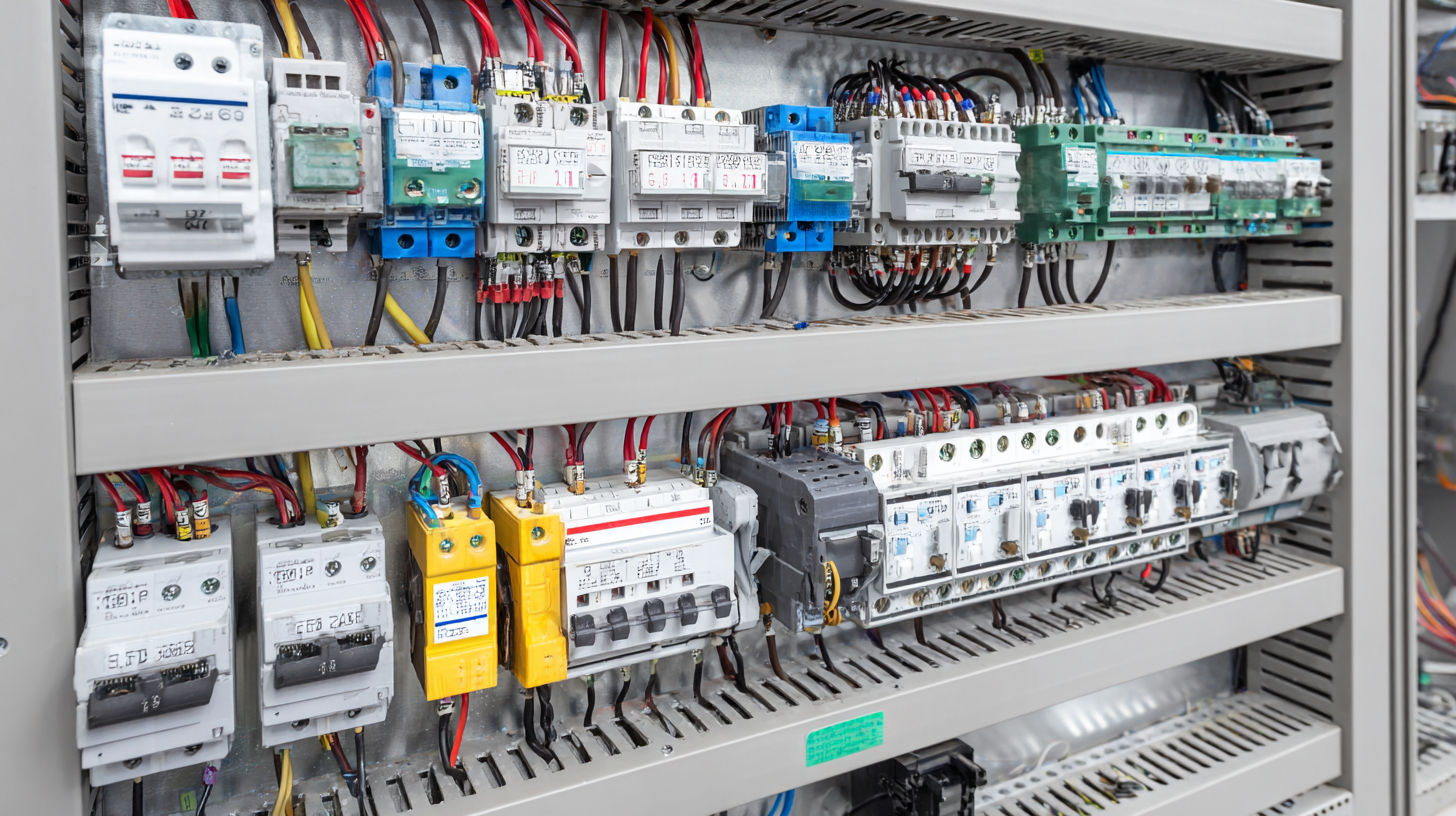

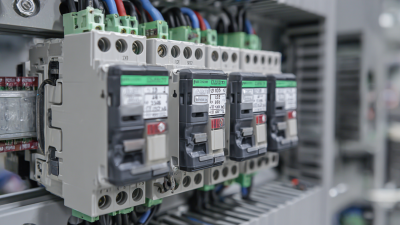

Motor protection relays play a crucial role in safeguarding electrical systems and ensuring operational efficiency. One of the key features of effective motor protection relay systems is their ability to detect various fault conditions, such as overloads, short circuits, and phase failures. These relays are designed with sophisticated algorithms that can quickly analyze electrical parameters, thus allowing for real-time monitoring of motor performance. By promptly identifying abnormalities, they can initiate quick responses to prevent equipment damage and sustain system integrity.

Another significant characteristic is the versatility of motor protection relays in communication. Modern systems often incorporate advanced communication protocols, allowing for seamless integration with supervisory control and data acquisition (SCADA) systems. This connectivity enables the relay to transmit operational data and alerts remotely, facilitating easier maintenance and quicker decision-making. Additionally, features like adjustable settings for trip points help customize the relay's response to varying operational conditions, enhancing overall reliability and protection tailored to specific motor applications.

Comparative Analysis of Motor Protection Relay Technologies

The significance of motor protection relays (MPRs) in electrical safety systems cannot be overstated. With the rapid advancement in technology, MPRs have evolved, offering various features that enhance grid resilience, especially in distributed energy systems. Recent studies highlight the importance of evaluating different MPR technologies through comparative analysis. This approach not only aids in understanding the diverse functionalities of these relays but also assists operators in selecting the most suitable options for their specific applications. For instance, research indicates that advanced MPRs can reduce the fault response time by up to 50%, leading to improved safety and operational efficiency.

Furthermore, with an increasing focus on integrating renewable energy sources, the need for robust fault detection mechanisms has become paramount. A comprehensive review of various islanding detection methods has demonstrated significant variations in performance, prompting a stronger push toward optimizing fault detection frameworks. In DC microgrids, where multiple energy sources are utilized, enhanced reliability can be achieved through integrated fault detection and control mechanisms. Reports suggest that employing sophisticated analytic techniques in MPR technologies can lead to a 30% increase in overall system reliability, showcasing the pivotal role these devices play in modern electrical safety systems.

Understanding the Importance of Motor Protection Relay in Electrical Safety Systems - Comparative Analysis of Motor Protection Relay Technologies

| Relay Type | Trip Settings | Communication Protocol | Protection Features | Typical Applications |

|---|---|---|---|---|

| Electromechanical Relay | Overload, Short Circuit | None | Overcurrent, Earth Fault | Industrial Motors |

| Digital Relay | Customizable Settings | Modbus, TCP/IP | Overload, Voltage, Phase Failure | HVAC Systems |

| Microprocessor-based Relay | Flexible Current Ratings | GSM, Ethernet | Comprehensive Protection (Voltage, Frequency) | Renewable Energy Systems |

Integration of Motor Protection Relays in Safety Protocols

The integration of motor protection relays into electrical safety protocols plays a crucial role in enhancing the overall safety and reliability of industrial systems. These relays serve as the first line of defense against potential motor failures, providing essential functions such as overload protection, short-circuit detection, and thermal monitoring. By incorporating motor protection relays into safety protocols, organizations can ensure that motors operate within their specified limits, thus preventing damage and reducing downtime. This integration not only safeguards equipment but also fosters a safer work environment, protecting personnel from electrical hazards.

Moreover, the implementation of motor protection relays allows for real-time monitoring and diagnostic capabilities within safety protocols. Advanced relays can communicate operational data, enabling predictive maintenance practices that help identify potential issues before they escalate into major failures. This proactive approach means that maintenance teams can address concerns efficiently, ultimately reducing operational costs and increasing productivity. By embracing the integration of motor protection relays into safety protocols, industries can achieve a robust electrical safety framework that prioritizes both equipment longevity and worker safety.

Best Practices for Maintaining and Testing Motor Protection Relays

Regular maintenance and testing of motor protection relays are essential for ensuring the reliability and safety of electrical systems. These devices monitor motor conditions and protect against faults such as overloads, short circuits, and phase failures.

To maintain optimal performance, it is crucial to conduct routine inspections, which should include checking the relay settings, verifying calibration, and examining electrical connections for signs of wear or corrosion.

Additionally, periodic cleaning of the relay contacts and ensuring proper operational environment can significantly enhance longevity and accuracy.

Regular maintenance and testing of motor protection relays are essential for ensuring the reliability and safety of electrical systems. These devices monitor motor conditions and protect against faults such as overloads, short circuits, and phase failures.

To maintain optimal performance, it is crucial to conduct routine inspections, which should include checking the relay settings, verifying calibration, and examining electrical connections for signs of wear or corrosion.

Additionally, periodic cleaning of the relay contacts and ensuring proper operational environment can significantly enhance longevity and accuracy.

Testing these relays should be carried out at defined intervals using specialized equipment to simulate various fault conditions. Functional tests can verify that the relay responds correctly to overload conditions, while insulation resistance tests can help identify potential breakdowns in the system.

It is also advisable to keep detailed records of all maintenance and testing activities, as this data can help analyze trends over time and inform future actions. By prioritizing these best practices, facilities can ensure their motor protection relays contribute effectively to overall electrical safety and operational efficiency.

Related Posts

-

Ultimate Guide to Understanding Motor Protection Solutions for Industrial Applications

-

7 Essential Tips for Choosing the Right Electric Breaker for Your Needs

-

Ultimate Guide to ACB Breaker Selection and Maintenance for Optimal Performance

-

Exploring MCCB Circuit Breaker Innovations at the 138th Canton Fair 2025 in China

-

7 Essential Tips for Choosing the Right Air Circuit Breaker for Your Electrical Systems

-

Understanding the Importance of DC Switches in Modern Electrical Systems