Understanding the Importance of MCCB Breakers in Modern Electrical Systems

In today's rapidly advancing technological landscape, ensuring the safety and efficiency of electrical systems is more crucial than ever. Among the critical components that play a pivotal role in modern electrical infrastructure are MCCB breakers (Molded Case Circuit Breakers). These devices not only provide essential overcurrent protection but also contribute significantly to the reliability and longevity of electrical installations. With the increasing complexity of electrical loads and the need for adaptive solutions, understanding the functioning and advantages of MCCB breakers becomes imperative for engineers, electricians, and facility managers. Their ability to manage higher fault currents and handle varying operational conditions makes MCCB breakers indispensable in both commercial and industrial applications. This article delves into the importance of MCCB breakers, highlighting their features, benefits, and the essential role they play in safeguarding modern electrical systems.

Understanding MCCB Breakers: Key Features and Functions

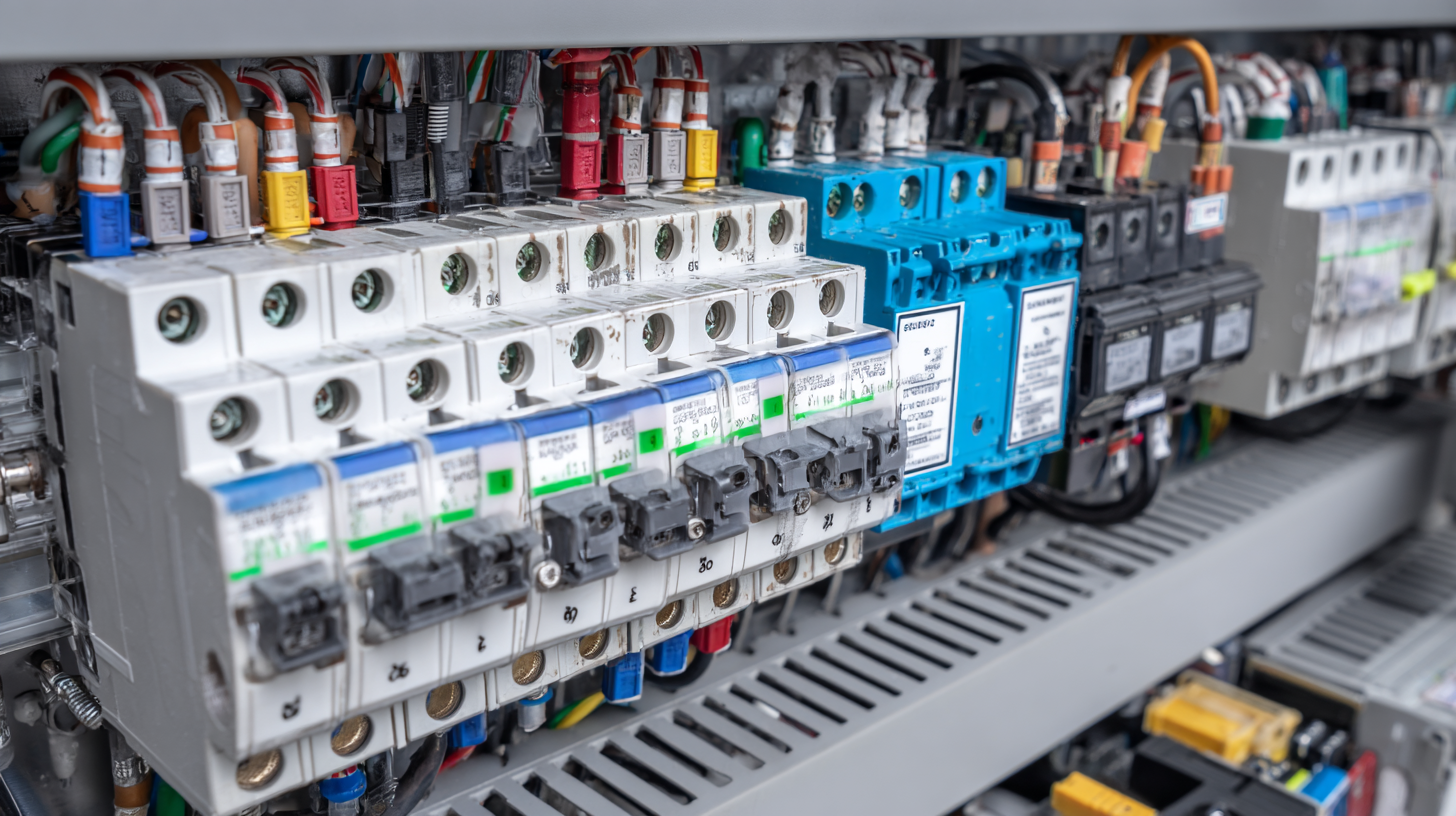

MCCB (Molded Case Circuit Breaker) breakers are crucial components in modern electrical systems, offering a range of features and functions that enhance both safety and efficiency. One of their key features is the ability to provide overcurrent protection, which safeguards circuits from overloads and short circuits. This is particularly important in industrial and commercial settings where equipment and machinery can draw significant current. Additionally, MCCB breakers often come with adjustable trip settings, allowing for customization based on specific load requirements.

Tips: When selecting an MCCB breaker, consider the application type and the expected load. It's essential to choose a breaker with an appropriate voltage rating and current-carrying capacity to ensure reliable performance. Regular maintenance checks can also help in identifying potential issues before they lead to system failures.

Furthermore, the ability of MCCBs to provide an easy means of manual circuit interruption enhances user control over electrical systems. Features like visual indicators for trip status and modular designs for easy installation and replacement make these breakers user-friendly. This combination of safety and convenience makes MCCB breakers indispensable in contemporary electrical systems, promoting both operational efficiency and protecting vital equipment.

Understanding the Importance of MCCB Breakers in Modern Electrical Systems

| Feature | Description | Importance |

|---|---|---|

| Overload Protection | MCCB breakers provide protection against excessive current draw which can lead to overheating and potential fire hazards. | Prevents electrical fires and damages to equipment. |

| Short-Circuit Protection | Designed to trip when a short-circuit occurs, cutting off power and preventing further damage. | Protects electrical systems from high fault currents. |

| Adjustable Settings | Many MCCB breakers allow for customization in trip settings for various applications. | Provides flexibility to adapt to different load requirements. |

| Easy Maintenance | MCCB breakers are designed for easy inspection and maintenance to ensure reliability. | Promotes quick identification of issues and reduces downtime. |

| Compact Design | Modern MCCB breakers are designed to take up minimal space, which is ideal for various installations. | Facilitates installation in crowded electrical panels. |

Choosing the Right MCCB for Your Electrical System Needs

When selecting the right Molded Case Circuit Breaker (MCCB) for your electrical system, it is crucial to consider several factors to ensure optimal performance and safety. First, assess the electrical load of your system. Understanding the total amperage demands will help determine the appropriate MCCB rating. The breaker should be rated above the maximum expected load but below any potential fault currents to protect the system effectively.

Additionally, consider the type of application and environment in which the MCCB will be installed. Different environments may require specialized features such as increased resistance to dust, moisture, or corrosive elements. Moreover, it’s essential to evaluate the breaker’s trip characteristics, as these determine how an MCCB responds to overload and short circuit conditions. Selecting an MCCB with the right trip curve—whether standard, inverse, or long-time—ensures that the protection aligns with the system's requirements, enhancing reliability and safety.

Installation Tips for Maximizing MCCB Breaker Performance

When installing MCCB (Molded Case Circuit Breaker) breakers, proper placement and configuration are critical for ensuring optimal performance and safety. First, it is essential to select an appropriate size and rating for the MCCB based on the electrical load it will support. Oversizing or undersizing the breaker can lead to inefficiency and potential damage to the electrical system. Additionally, ensure that the installation area is clean and free from moisture and dust, as these factors can negatively impact the breaker's functionality.

Furthermore, proper wiring is vital. Use the recommended gauge and type of wire to match the MCCB specifications, and make sure all connections are tight and secure to prevent overheating. Regular maintenance checks, including visual inspections and testing of the test button, can help detect issues early. It’s advisable to label circuits accurately during installation, making it easier for future troubleshooting and maintenance. Consider seeking professional assistance if unsure about the installation process, as this will help maximize the lifespan and reliability of the MCCB breaker in your electrical system.

Maintenance Practices to Ensure MCCB Reliability and Longevity

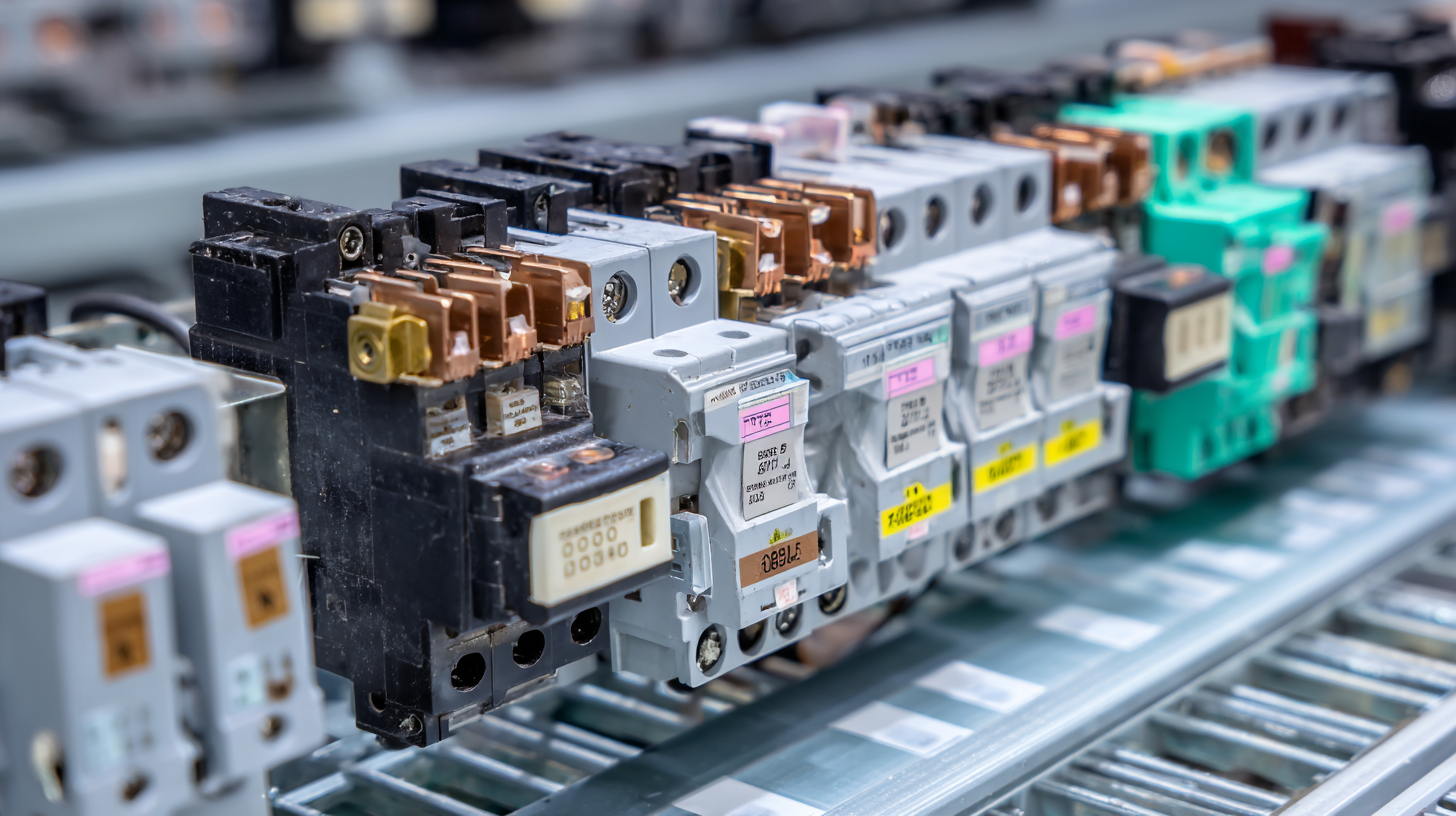

Regular maintenance of Molded Case Circuit Breakers (MCCBs) is essential to ensuring their reliability and longevity in modern electrical systems. One of the key practices is to conduct periodic inspections to assess the physical and operational condition of the breakers. This involves checking for signs of wear, corrosion, or thermal damage, which can compromise their functionality. Additionally, cleaning the components to remove dust and debris can prevent overheating and ensure smooth operation.

Another important aspect of maintenance is testing the MCCBs to confirm their trip settings and response times. This can involve using specialized testing equipment to simulate fault conditions and verifying that the breakers operate as intended. Furthermore, documenting these tests and inspections creates a valuable maintenance history that can inform future practices and highlight any emerging trends. By implementing these maintenance practices, facility managers can significantly enhance the performance and lifespan of MCCBs, thereby safeguarding the entire electrical system from potential failures.

Understanding the Importance of MCCB Breakers in Modern Electrical Systems

This chart illustrates the maintenance frequency and its correlation with MCCB reliability and longevity. Regular maintenance is critical to ensure optimal performance of MCCB breakers in electrical systems.

Troubleshooting Common Issues with MCCB Breakers in Use

Molded Case Circuit Breakers (MCCBs) play a critical role in safeguarding electrical systems, yet troubleshooting common issues with these devices can be challenging. A study by ResearchAndMarkets, published in early 2023, highlighted that almost 30% of electrical faults within industrial settings are linked to faulty or improperly maintained MCCBs. Problems such as trip settings not aligning with system requirements, lack of regular maintenance, or environmental factors like humidity can lead to unnecessary downtime.

One prevalent issue is nuisance tripping, which often results from parameters being set too sensitively. According to a report by the Electrical Safety Foundation International (ESFI), approximately 20% of MCCB failures are attributed to incorrect adjustments or settings. Regular calibration and testing, as recommended by the National Electrical Manufacturers Association (NEMA), can significantly reduce these failures. Additionally, visual inspections to detect signs of wear or damage, along with thermal imaging to identify hot spots, can help operators maintain system integrity and ensure reliable performance.

Related Posts

-

Exploring MCCB Circuit Breaker Innovations at the 138th Canton Fair 2025 in China

-

Exploring Market Trends for Switch Disconnectors at the 138th Canton Fair 2025 in China

-

How to Choose the Right Motor Protection Relay for Your Application

-

How to Choose the Right Circuit Protection Solutions for Your Devices

-

7 Essential Tips for Choosing the Right Air Circuit Breaker for Your Electrical Systems

-

10 Essential Tips for Surge Protection: Protect Your Electronics with 99% Effectiveness!