When it comes to electrical distribution systems, selecting the right equipment is crucial, and choosing a high-quality dry transformer is no exception. Dry transformers, known for their reliability and efficiency, are essential components that convert voltage levels to suit your operational needs. In this ultimate guide, we will explore the key factors to consider when selecting a dry transformer, including the various types available and their respective applications. Additionally, we will provide insights into identifying reputable manufacturers and solutions tailored to your specific requirements. Whether you are upgrading existing systems or embarking on a new project, understanding the nuances of dry transformers will empower you to make informed decisions that enhance performance and safety. Join us as we delve into the intricacies of dry transformer selection to help you find the best solution for your needs.

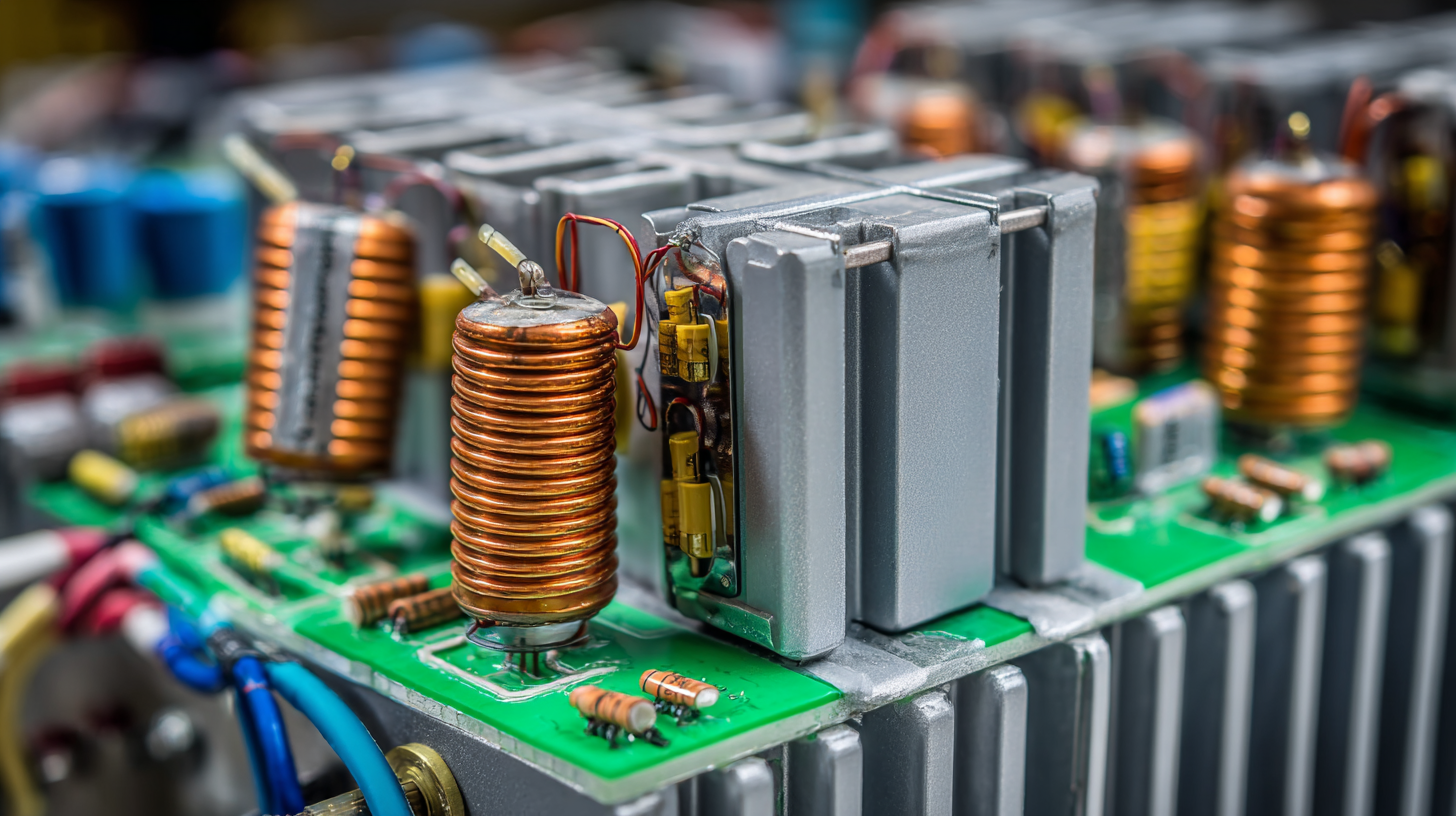

A dry transformer is a type of electrical transformer that utilizes air as its cooling medium instead of oil, making it a more environmentally friendly option. Understanding how dry transformers work is crucial for selecting the right one for your requirements. These transformers function by transferring electrical energy between two or more circuits through electromagnetic induction. They come equipped with insulation materials that are capable of withstanding high voltages, ensuring operational safety and reliability.

According to a recent industry report by Transparency Market Research, the global dry-type transformer market is expected to grow significantly, projected to reach $6.4 billion by 2027. This growth is largely driven by increasing infrastructure development and the rising demand for energy-efficient equipment. Dry transformers are particularly favored in urban areas due to their compact design and reduced fire hazards. Additionally, they are ideal for indoor installations, where space is limited, and safety regulations are stringent. Understanding these basics can assist in making informed decisions when navigating the complexities of electrical systems.

When selecting the best dry transformer for your specific needs, several key specifications must be considered to ensure optimal performance and efficiency. First and foremost, assess the transformer's voltage and power rating as these factors directly influence its ability to meet your energy demands. Dry transformers typically operate at various voltages and power ratings, so understanding your current and future requirements is crucial.

Another important consideration is the environment in which the transformer will be installed. Dry transformers are known for their insulation properties and reduced risk of environmental contamination, making them suitable for indoor installations or places where space is limited. Additionally, evaluate the transformer's thermal management capabilities, as effective cooling systems can prevent overheating and prolong the unit's lifespan. Pay attention to the materials used in construction, as high-quality components can significantly impact overall durability and maintenance needs. Understanding these specifications will guide you in making an informed choice tailored to your operational requirements.

When considering transformers, one of the primary decisions is choosing between

dry transformers and oil-immersed transformers.

Dry transformers, often used in indoor applications, are less prone to environmental hazards and require less maintenance. According to a report by MarketsandMarkets,

the global dry-type transformer market is projected to grow at a CAGR of 6.4% from 2022 to 2027, largely due to increasing infrastructure development and urbanization.

In contrast, oil-immersed transformers are known for their efficient heat dissipation and are commonly employed in outdoor settings for their robust design.

Tips: When evaluating your transformer options, consider the installation environment.

For locations with limited space or where safety is paramount, dry transformers may provide a better solution. In contrast, if the application

involves high power loads in expansive areas, oil-immersed transformers might be more efficient due to their cooling properties and capacity for larger power ratings.

Additionally, the total cost of ownership is an important factor. A study by McKinsey found that while dry transformers tend to have higher initial costs,

they offer lower operational and maintenance costs over their lifespan. This long-term perspective could make dry transformers a more sustainable choice

for many companies as they transition to more environmentally friendly solutions.

In 2023, the market for dry transformers is experiencing notable growth, reflecting a broader trend in the electrical engineering sector. The three-phase distribution transformer market alone surpassed USD 12.9 billion this year, with projections indicating a robust compound annual growth rate (CAGR) of over 9.4% through 2032. This surge is driven by increasing energy demands and a push towards more efficient electrical infrastructure.

Furthermore, niche segments like the data center transformer market are also set to thrive, with an expected growth of USD 11.25 billion at a 6.3% CAGR by 2032, highlighting the evolving energy needs of modern technology environments. The green power transformer market is particularly noteworthy, anticipated to reach USD 30.8 billion, growing at an impressive CAGR of 19.32%. This reflects a significant shift toward sustainable energy solutions, indicating that industries are increasingly focusing on eco-friendly and efficient transformer options in response to growing environmental concerns.

When it comes to dry transformers, maintenance is key to ensuring longevity and efficiency. According to a recent industry report by the Institute of Electrical and Electronics Engineers (IEEE), regular maintenance can enhance the operational life of transformers by up to 40%. It’s essential to perform routine inspections to check for common issues such as insulation degradation and overheating. Keeping the environment clean and free from contaminants greatly reduces the risk of failures, contributing to optimal performance.

Tip: Schedule monthly visual inspections to identify any potential issues before they become major problems. Additionally, consider thermographic scans to detect hot spots that may indicate an insulation failure.

Proper storage of dry transformers is also crucial. The Electrical Engineering Handbook suggests storing transformers in a controlled environment to avoid humidity and temperature fluctuations, which can adversely affect the insulation material over time. Alongside this, regular functionality testing should be conducted every six months to ensure electrical parameters are within acceptable ranges.

Tip: Implement a detailed maintenance schedule that includes both visual inspections and functional tests, ensuring that all aspects of transformer health are addressed systematically.