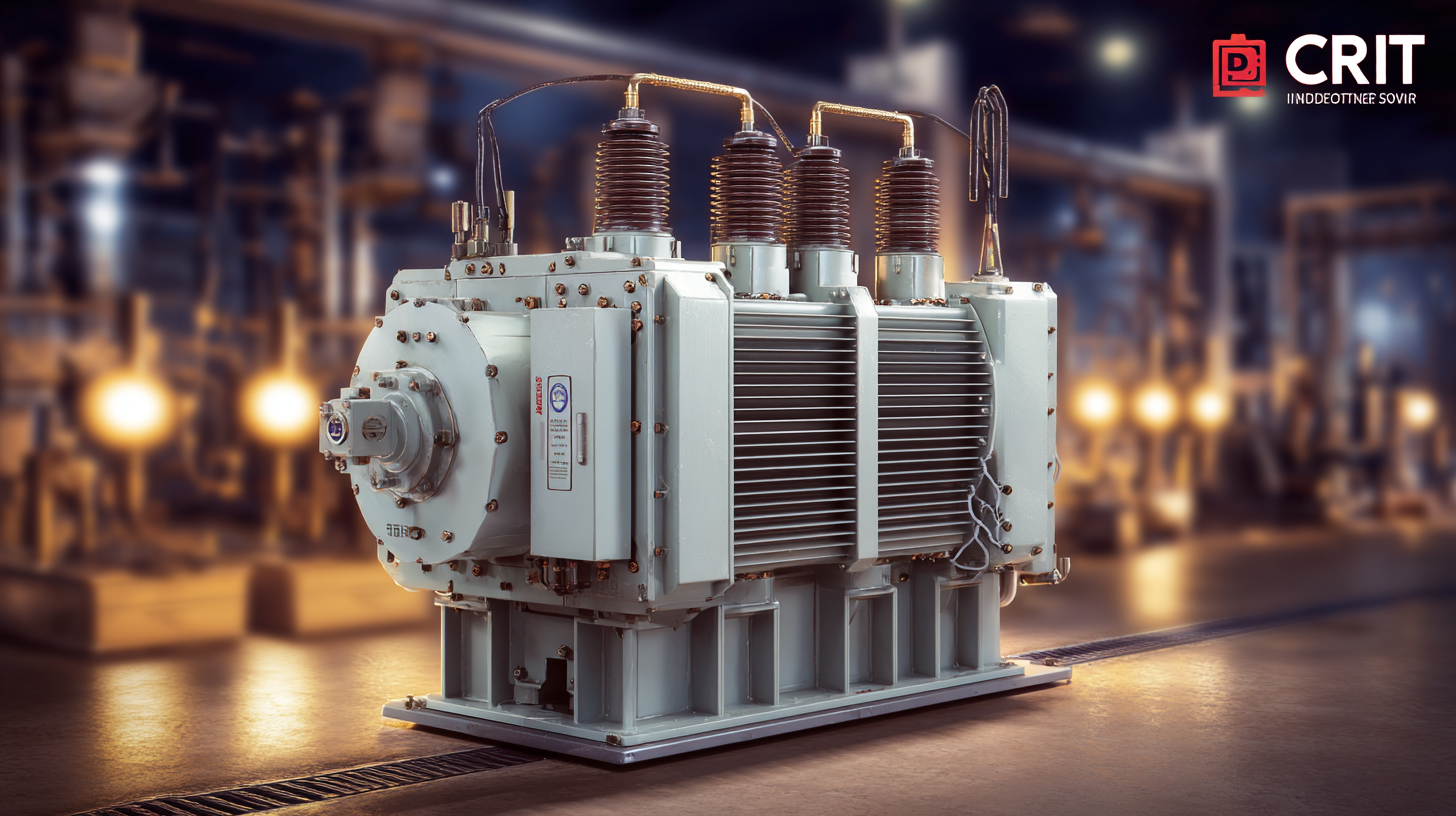

As the global demand for reliable and efficient power distribution systems continues to rise, the market for Oil Immersed Transformers is projected to witness significant growth, with estimates suggesting a valuation of approximately $20 billion by 2025, according to industry reports. These transformers are crucial in facilitating the management of electrical energy, especially in high-voltage applications, where their ability to dissipate heat efficiently plays a vital role in maintaining performance and longevity. However, common issues such as insulation degradation, oil contamination, and operational inefficiencies pose challenges that need to be addressed. This blog aims to explore these issues and provide practical solutions through a comprehensive analysis of the state of the Oil Immersed Transformer industry, examining best practices, maintenance strategies, and technological advancements that can enhance reliability and efficiency in the coming years.

Oil immersed transformers are known for their remarkable efficiency, often exceeding 98%. This high level of performance can be attributed to several key factors. First and foremost, the design of these transformers enables optimal heat dissipation. The oil serves not only as an insulator but also as a coolant, ensuring that the transformer maintains stable operating temperatures. This temperature control minimizes energy losses associated with resistance heating, contributing to overall efficiency.

Another critical aspect is the quality of materials used in the construction of oil immersed transformers. High-grade electrical steel and advanced insulation materials help reduce core losses and enhance conductivity. Additionally, these transformers are often equipped with modern technologies such as active monitoring and smart grid capabilities, allowing for real-time assessment of performance and maintenance needs. Consequently, oil immersed transformers stand out in their reliability and effectiveness, making them a preferred choice for various industrial applications.

Oil immersed transformers are critical components in electrical distribution systems, yet they are not without their challenges. This blog addresses five common issues that can significantly impact the reliability of these transformers. One prevalent concern is overheating, which occurs due to poor cooling and can accelerate insulation failure. According to a report by the IEEE, nearly 50% of transformer failures result from thermal overload.

Another issue is moisture ingress, which can lead to a breakdown of the insulating oil. The presence of water can reduce the oil's dielectric strength, increasing the risk of short circuits and equipment failure. A study conducted by the International Electrotechnical Commission (IEC) indicates that moisture levels exceeding 30 ppm can drastically affect transformer performance.

**Tip:** Regularly monitoring the insulation and cooling systems can help identify overheating early.

Lastly, mechanical failures, such as those from loose connections or corrosion, can disrupt operational efficiency. Data from industry surveys show that 35% of transformer breakdowns are linked to mechanical issues.

**Tip:** Conducting periodic maintenance and inspections can prevent these failures and extend the service life of oil immersed transformers.

| Issue | Description | Impact on Reliability | Possible Solutions |

|---|---|---|---|

| Oil Leakage | Loss of insulating oil due to faulty seals or damage. | Reduced insulation strength can lead to failure of transformer. | Regular inspections and timely replacement of seals. |

| Overheating | Excessive heat generated from overload or poor ventilation. | Decreased lifespan and risk of catastrophic failure. | Ensure proper load management and improve cooling systems. |

| Contamination | Dirt and moisture entering the transformer oil. | Increases breakdown voltage and degrading oil quality. | Use of proper filters and maintaining oil purity. |

| Aging Insulation | Deterioration of insulation materials over time. | Increases the risk of short circuits and transformer failure. | Regular testing and maintenance of insulation quality. |

| Faulty Components | Failure of internal components like bushings or tap changers. | Can lead to operational failures and unpredictable outages. | Regular inspections and replacing worn components proactively. |

When it comes to the longevity and reliability of oil immersed transformers, several key factors come into play. One of the primary influences is the quality of the insulating oil. High-quality oil not only provides better electrical insulation but also absorbs heat more effectively, thereby reducing the risk of overheating. Regular testing and maintenance of the oil can significantly enhance the transformer's lifespan, ensuring that contaminants don't compromise its performance.

Another critical factor is the operating environment. Extreme temperatures, moisture, and chemical exposure can deteriorate both the transformer and its insulating oil. Proper housing and location selection can mitigate these risks. Additionally, regular monitoring of temperature and load levels is vital for maintaining optimal performance. Overloading the transformer can lead to premature aging and potential failure, highlighting the importance of adhering to recommended load limits. By addressing these key factors, operators can enhance the reliability and functionality of oil immersed transformers, ultimately extending their operational life.

Maintaining oil immersed transformers is essential not only for operational efficiency but also for managing costs effectively. Regular upkeep can lead to significant savings, with studies suggesting that consistent maintenance can reduce overhaul expenses by as much as 30%. This is a critical insight for industries reliant on transformer technology, where unexpected failures can incur substantial costs and disrupt operations.

By investing in a proactive maintenance strategy, organizations can avoid the costly repercussions of neglect. Similar to how vehicle maintenance plays a crucial role in prolonging the lifespan of cars—with average annual maintenance costs for certain brands reaching nearly $1,000—transformer owners must prioritize scheduled inspections and timely repairs. Analytics-based maintenance strategies further enhance this approach, allowing for predictive insights that inform timely interventions and reduce the likelihood of catastrophic failures.

Additionally, transforming maintenance practices to align with analytics-driven models can create significant value. Just as hospitals are increasingly utilizing home care initiatives to lower costs while improving patient outcomes, industries should adopt innovative maintenance solutions that leverage technology. By doing so, they not only optimize performance but also achieve considerable financial efficiency, echoing the findings that regular maintenance can yield substantial savings in overhaul expenses.

Oil immersed transformers are crucial for power distribution, yet they come with safety concerns that need to be addressed. Here, we focus on three major safety issues: risk of fire, leakage of harmful substances, and thermal management failures.

Firstly, the risk of fire can occur due to overheating or faults in insulation. Implementing advanced monitoring systems can significantly mitigate this risk. Regular maintenance and thermographic inspections can help identify hotspots before they lead to catastrophic failure.

Secondly, leakage of oil can pose environmental hazards. Utilizing robust containment measures and increasing the frequency of inspections can help ensure that any leaks are detected early. Moreover, incorporating innovations like robotic inspections can reduce the risk to personnel while enhancing the detection of potential issues.

Finally, thermal management is vital to the reliability of oil immersed transformers. Exploring immersion cooling technologies not only improves efficiency but also enhances safety by maintaining optimal operating temperatures. As the demand for reliable and eco-friendly power solutions grows, addressing these safety concerns will be essential in ensuring the sustainability and efficiency of our electrical infrastructure.