How to Choose the Best Laboratory Sample Pulverizer for Your Needs?

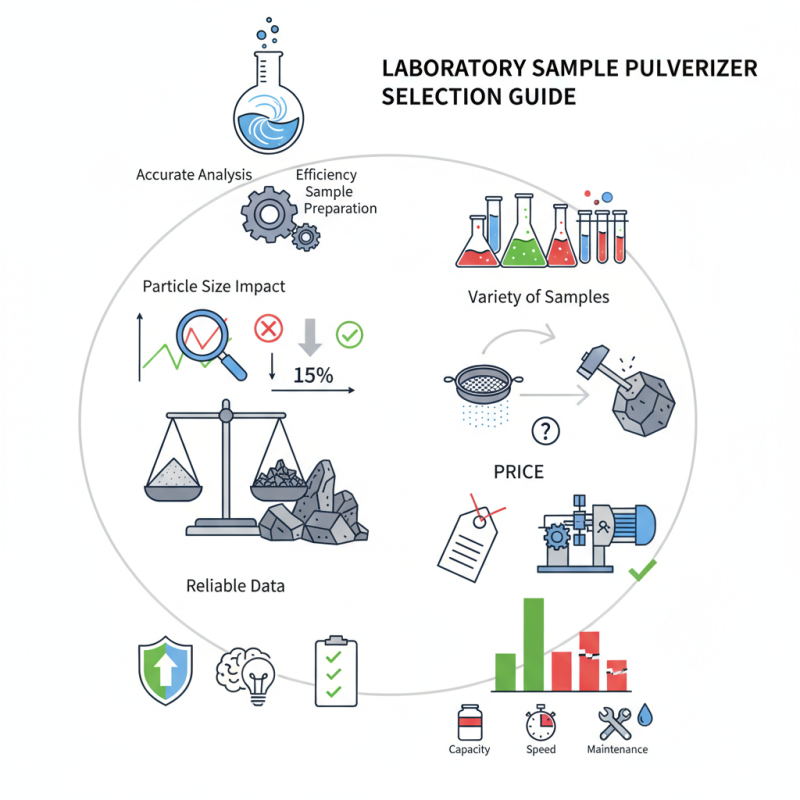

Choosing the right laboratory sample pulverizer is crucial for accurate analysis. A suitable pulverizer can enhance the efficiency of sample preparation. According to industry reports, precision in sample particle size directly impacts test results. For instance, a study shows that inconsistent particle size can lead to a 15% variance in outcomes.

In laboratory settings, the variety of samples demands different pulverizing methods. Some tasks require fine powders, while others need coarser materials. This variability complicates the selection process. Only a few models meet the diverse needs of laboratories. Yet, many researchers often overlook performance specifications, focusing instead on price.

While numerous options exist, not all are effective. Many laboratory sample pulverizers fall short in durability and consistency. Choosing a subpar option can lead to wasted resources and unreliable data. It’s vital to evaluate features thoroughly. Consider capacity, speed, and maintenance needs to ensure the best results.

Understanding the Role of Laboratory Sample Pulverizers in Research

Laboratory sample pulverizers play a critical role in research. They help scientists prepare materials for analysis. This preparation is crucial for accurate results. A recent industry report shows that proper sample size reduction can improve analysis accuracy by up to 30%. Researchers must select the right pulverizer to meet their specific needs.

Different pulverizers serve various purposes. Some are designed for hard materials, while others work better with softer samples. For instance, cutting mills are ideal for fibrous materials. In contrast, planetary ball mills excel at grinding hard materials like minerals. A mismatch in equipment can lead to less reliable data. Data shows that poor sample preparation can invalidate 20% of test results.

The efficiency and speed of sample reduction also matter. Some labs require quick results. Others might prioritize precision. It is not always easy to balance these needs. Scientists often face challenges when finding the right equipment. The process can lead to frustration as they seek the best solution for their work. Understanding these nuances is vital for effective research outcomes.

Key Factors to Consider When Selecting a Pulverizer

When selecting a laboratory sample pulverizer, several factors play a critical role. The type of material you plan to process is essential. Different materials require specific grinding techniques. For instance, hard samples may need more powerful motors. In a recent industry report, it was noted that nearly 30% of pulverizer failures stem from inappropriate material compatibility.

Another key factor is the desired particle size. Achieving precise particle sizes is crucial for accurate testing results. Many laboratories target sizes of 40 microns or finer. If a pulverizer can't reach these specifications, it could compromise your research. A study by a leading materials science journal found that particle size directly impacts the chemical properties of samples, highlighting the need for an appropriate choice.

Lastly, consider maintenance and ease of use. Some pulverizers may require specialized training. This can lead to operational delays. A user survey indicated that 25% of lab technicians felt overwhelmed by complex equipment. Balancing user-friendliness with performance is vital. Reflect on how each of these factors aligns with your lab’s specific requirements.

How to Choose the Best Laboratory Sample Pulverizer for Your Needs? - Key Factors to Consider When Selecting a Pulverizer

| Factor | Description | Importance Level |

|---|---|---|

| Material Type | Determine the sample materials you will be processing (e.g., rocks, ores, biological samples). | High |

| Particle Size Requirement | Identify the required final particle size for your samples. | Medium |

| Power Source | Consider whether you need an electric or manual pulverizer based on your lab setup. | Medium |

| Sample Volume | Assess how much sample volume you need to process at one time. | High |

| Ease of Use | Evaluate how user-friendly the pulverizer is for your staff. | High |

| Maintenance and Cleaning | Consider how easy it is to maintain and clean the pulverizer. | Medium |

| Cost | Analyze your budget for purchasing a pulverizer. | High |

| Safety Features | Look for features that protect the user during operation. | High |

Types of Laboratory Sample Pulverizers and Their Applications

Laboratory sample pulverizers come in various types, each tailored for specific applications. A common type is the planetary ball mill. It effectively grinds samples to a fine powder. This method is ideal for materials that require homogenization. Another popular choice is the disc pulverizer. It provides a more direct grinding action. This is beneficial for brittle materials. Each device serves a unique purpose, and understanding these functions is critical.

Choosing the right pulverizer depends on your specific needs. Consider the material type and desired particle size. For example, if you work with hard minerals, you might prefer a more robust device. On the other hand, softer materials may not need such heavy-duty equipment. It's easy to underestimate the importance of sample size and feed rate. Finding the right balance is essential for effective results.

Many users overlook maintenance needs. Regular upkeep is vital for optimal performance. A well-maintained pulverizer will yield consistent results. However, not everyone prioritizes this step. Be mindful of your choice and its implications. The right laboratory sample pulverizer can significantly affect your workflow and outcomes.

Types of Laboratory Sample Pulverizers and Their Applications

Evaluating Performance and Efficiency of Pulverizers

When selecting a laboratory sample pulverizer, evaluating performance and efficiency is crucial. A good pulverizer should reduce samples to precise particle sizes. Research indicates that particle size affects material properties significantly. For instance, a reduction in size often enhances the reactivity of chemicals. According to a recent industry report, samples processed to 100 microns displayed a 30% increase in dissolution rates.

Efficiency also comes into play during operation. Some pulverizers operate at varying speeds to optimize energy use. A study found that machines running at 5,000 RPM were 25% more efficient than those at lower speeds. However, faster isn't always better. Overheating can occur, damaging the material and affecting results. It's essential to balance speed with cooling mechanisms for optimal performance.

Moreover, maintenance routines impact longevity and efficiency. Inadequate upkeep might lead to wear and tear, reducing the pulverizer’s effectiveness. A survey indicated that neglecting regular checks can result in a 15% drop in output quality. Users should reflect on their operational habits. An efficient pulverizer might falter if not maintained properly. Investing time in understanding these factors becomes vital for achieving the desired results.

Budget Considerations and Cost-Effectiveness in Purchasing

When considering the purchase of a laboratory sample pulverizer, budget plays a crucial role. A recent industry report noted that 45% of laboratories prioritize cost-effectiveness in their purchasing decisions. It's essential to balance initial costs with long-term maintenance expenses. A pulverizer that seems cheaper upfront may require costly repairs or frequent replacement parts later.

Many users overlook the operational costs associated with different models. For example, energy-efficient pulverizers can save up to 30% on electricity bills. This saving can add up significantly over time. Moreover, a model that operates faster can increase productivity, ultimately saving money. However, a higher initial investment might be necessary.

Reflecting on potential pitfalls, some laboratories fail to consider how a pulverizer affects sample integrity. Quality can sometimes come at a price. Some models may not meet specific analytical standards, leading to compromised results. Evaluating features and your specific needs is vital. A well-researched choice can eventually enhance your laboratory’s efficiency and accuracy, outweighing the initial financial burden.