How to Choose the Best Soft Starter for Your Electrical Projects

In the realm of electrical engineering and motor control, the importance of soft starters cannot be overstated. As industries increasingly prioritize efficiency and longevity within their operations, the adoption of soft starters has surged. According to a recent market report by ResearchAndMarkets, the global soft starter market is projected to grow at a CAGR of approximately 5.2% from 2023 to 2028, reflecting the critical role these devices play in reducing inrush current and enhancing motor performance. This trend is driven by industrial sectors such as manufacturing, HVAC, and water treatment, where controlled acceleration and deceleration are vital to preventing mechanical stress and extending the lifespan of equipment.

Selecting the right soft starter for your electrical projects can significantly impact overall system performance and energy efficiency. A soft starter is designed to limit the initial surge of current during motor start-up, thus mitigating damage to electrical components and ensuring a smooth operation. As per a report published by MarketsandMarkets, the demand for energy-efficient solutions has prompted innovations in soft starter technology, including features like advanced microprocessor control and integration with modern automation systems. With an array of options available in the market, understanding the fundamental aspects of soft starters is essential for engineers and project managers aiming to optimize their electrical systems. This guide will delve into key considerations when selecting the most suitable soft starter for your specific applications.

Understanding Soft Starters: Definition and Purpose in Electrical Systems

Soft starters are essential devices used in electrical systems to manage the start-up phase of electric motors. Unlike traditional methods that apply full voltage immediately, soft starters gradually increase the voltage, allowing for a smoother ramp-up in speed. This gradual approach minimizes the mechanical stress on motor components and reduces electrical surges that can affect the overall system performance. By controlling the acceleration of the motor, soft starters not only enhance the longevity of the equipment but also contribute to energy efficiency.

In addition to reducing wear and tear, soft starters play a vital role in improving system stability. They are particularly useful in applications where sudden starts can lead to voltage drops or fluctuations in power supply, potentially causing other connected devices to malfunction. Understanding the function and benefits of soft starters is crucial for any electrical project. When appropriately selected and implemented, these devices can lead to a more reliable and efficient operation, ultimately resulting in cost savings over time due to decreased maintenance and downtime.

Key Specifications to Consider When Selecting a Soft Starter

When selecting a soft starter for electrical projects, it’s crucial to consider several key specifications to ensure optimal performance and compatibility with your systems. One of the primary specifications is the current rating, which should reflect the load requirements of your motor. Industry standards suggest that the soft starter should be rated at 125% of the motor’s full load current to accommodate inrush currents during startup, which can be significantly higher than normal operating currents. According to a report by the International Electrotechnical Commission (IEC), improper selection can lead to most failures around the starting phase, emphasizing the need for correct current specifications.

Another important aspect to consider is the control method. Soft starters generally employ either voltage ramp or current limit control techniques. Voltage ramp control gradually increases the voltage applied to the motor, helping to reduce mechanical stress and power surges. In contrast, current limit control provides a defined maximum current level during startup, preventing overload conditions. Research published by the Electric Power Research Institute (EPRI) indicates that utilizing the optimal control method can enhance the lifespan of electrical components and improve overall energy efficiency, thus corroborating the importance of this specification in your decision-making process.

Evaluating Soft Starter Ratings: Amperage, Voltage and Control Features

When selecting a soft starter for your electrical projects, understanding the ratings associated with amperage and voltage is crucial. Amperage ratings indicate the maximum current the soft starter can handle. This is essential for ensuring that your electrical system can manage the initial surge of power when motors start. Choosing a soft starter with an appropriate amperage rating helps to prevent overheating and damage, ensuring reliable operation throughout the project.

Voltage ratings are equally important, as they specify the levels at which the soft starter can operate effectively. Make sure to match the voltage rating of the soft starter to that of your motor and overall system requirements. Additionally, considering control features is vital, as these features dictate how the soft starter manages the starting and stopping processes. Options such as ramp-up time, current limit settings, and built-in protection mechanisms can greatly enhance the performance and lifespan of your motors, making these control features an integral part of your decision-making process.

How to Choose the Best Soft Starter for Your Electrical Projects

| Model | Amperage Rating (A) | Voltage Rating (V) | Control Features | Protection Features |

|---|---|---|---|---|

| Soft Starter A | 25 | 220 | Soft Start, Stop Control | Overload Protection |

| Soft Starter B | 40 | 380 | Torque Control | Phase Failure Protection |

| Soft Starter C | 50 | 400 | Current Limit | Over Voltage Protection |

| Soft Starter D | 63 | 480 | Smart Start/Stop | Short Circuit Protection |

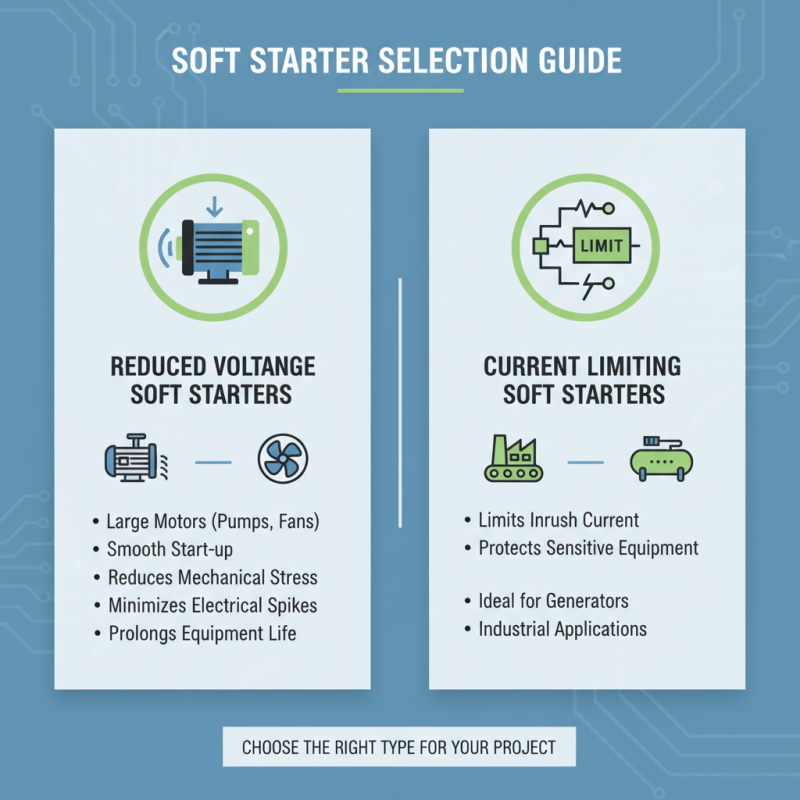

Comparing Different Types of Soft Starters for Specific Applications

When selecting a soft starter for your electrical project, it's crucial to understand the various types available and their specific applications. Two popular categories include reduced voltage soft starters and current limiting soft starters. Reduced voltage starters are commonly used for applications involving large motors, such as pumps and fans. They ease the motor into operation, reducing the mechanical stress and electrical spikes that can occur during startup. This not only prolongs the lifespan of the equipment but also minimizes disturbances in the power supply.

On the other hand, current limiting soft starters are ideal for environments where systems are sensitive to inrush currents. These starters function by limiting the initial current to a predetermined level, making them suitable for applications in industries such as mining and manufacturing, where sudden changes in current could damage machinery or interrupt production. By focusing on the specific characteristics and requirements of each application, you can make an informed choice that enhances efficiency and reliability in your projects.

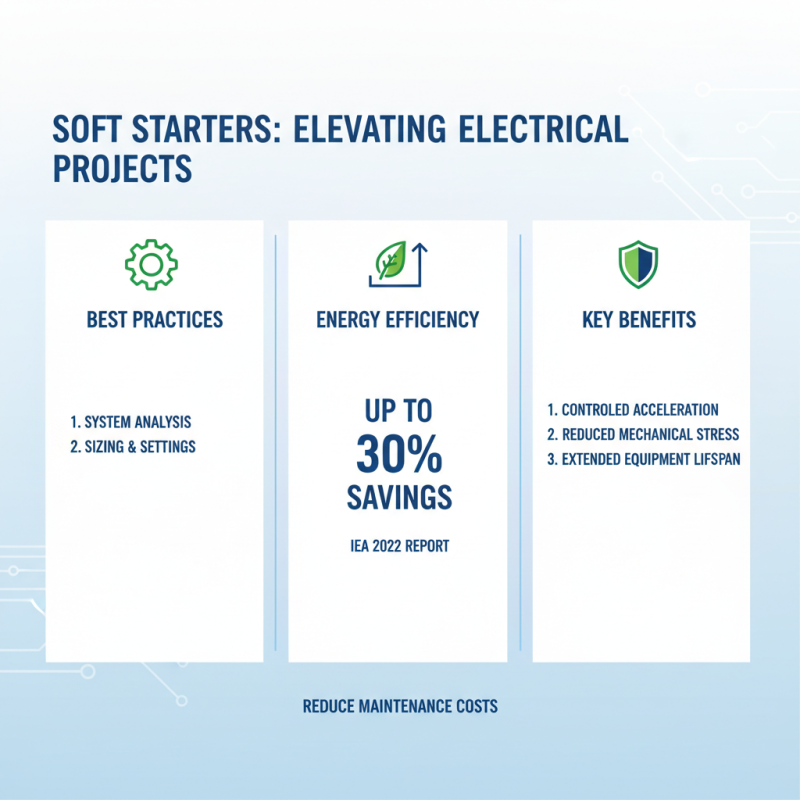

Industry Best Practices for Integrating Soft Starters into Projects

When integrating soft starters into electrical projects, industry best practices emphasize the importance of thorough system analysis and the selection of appropriate sizing and settings. According to a 2022 report by the International Energy Agency, implementing soft starters can enhance energy efficiency by as much as 30% in motor operations. This is achieved through controlled acceleration, reducing the mechanical stress on motors and associated equipment, which can significantly extend their operational lifespan and reduce maintenance costs.

Furthermore, it is recommended to consider the specific needs of the application when selecting a soft starter. For example, the voltage ratings and current capacities must align with the motor specifications to prevent overload and ensure optimal performance. The National Electrical Manufacturers Association (NEMA) suggests that utilizing features such as adjustable start time and current ramping can dramatically minimize inrush currents, leading to a more stable power supply. This not only protects the overall electrical infrastructure but also contributes to improving processing efficiency, as systems become less prone to failure and downtime.

In addition, training personnel on the proper installation and configuration of soft starters is essential. A study by the Electric Power Research Institute highlighted that installations that adhere to manufacturer guidelines reduce the likelihood of operational hiccups by nearly 50%. Continuous monitoring and periodic assessments post-installation can ensure that soft starters operate within their design limits, thereby maximizing their benefits in various electrical applications.

Related Posts

-

2025 Top Soft Starter Technologies for Efficient Motor Control

-

Top 10 MCCB Breakers: Choosing the Best Circuit Protection Solutions

-

Understanding the Challenges of Miniature Circuit Breakers in Modern Electrical Systems

-

Understanding Power Circuit Breakers: Key Features, Benefits, and Maintenance Tips for Home Safety

-

Top 10 Benefits of Using Vacuum Circuit Breakers for Your Electrical System

-

Exploring Market Trends for Switch Disconnectors at the 138th Canton Fair 2025 in China