2026 Best Molded Case Circuit Breaker Reviews and Buying Guide

Choosing the right molded case circuit breaker can seem overwhelming. This essential device protects electrical circuits from overloads and short circuits. A high-quality breaker can prevent costly damage and ensure safety in your electrical systems.

In this guide, we will explore the best molded case circuit breakers available in 2026. We’ll focus on aspects you should consider when buying. Features such as amperage ratings, trip settings, and durability matter. The right choice is vital for both residential and commercial applications.

Some products may excel in ratings but fail in real-world conditions. It’s important to reflect on your specific needs. Are you prioritizing safety or cost? These choices shape the long-term effectiveness of your molded case circuit breaker. Dive in and discover what suits your requirements.

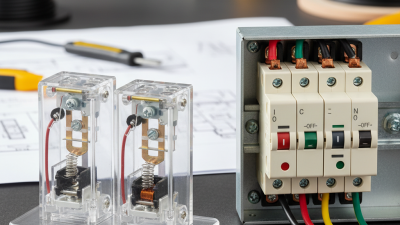

Overview of Molded Case Circuit Breakers and Their Applications

Molded case circuit breakers (MCCBs) play a crucial role in electrical systems. These devices protect circuits from overloads and short circuits. They automatically cut off the electrical supply when necessary. This ensures safety in residential, commercial, and industrial applications. MCCBs are versatile, able to handle a range of voltages and current levels.

In industrial settings, they safeguard equipment from damage. For example, they prevent motors from overheating. In homes, they protect sensitive electronics from power surges. However, choosing the right MCCB can be challenging. It’s important to evaluate the specific needs of your system. Consider factors like amperage, voltage, and application type.

Not all MCCBs are created equal. Some may fail to provide adequate protection in certain scenarios. This can lead to equipment damage or even safety hazards. Regular maintenance and testing of MCCBs is essential. Users must remain vigilant and proactive about potential issues. Understanding the applications and limitations of MCCBs is key to maximizing safety and effectiveness.

Key Features to Consider When Selecting a Molded Case Circuit Breaker

When selecting a molded case circuit breaker, several key features play a pivotal role. Consider the current rating; it must match your electrical system's needs. An incorrect rating can lead to malfunction or overheating. Look closely at the interrupting capacity. This spec indicates how much fault current the breaker can safely interrupt. A higher capacity is preferable for industrial applications.

Another important aspect is the trip settings. Adjustable trip settings offer flexibility for various electrical loads. This is critical in preventing nuisance tripping. Check for additional features like ground fault protection or arc fault detection. These features provide enhanced safety in residential and commercial settings.

One should also think about the physical size and mounting options. Ensure the breaker fits your panel and is easy to install. Reflect on the ease of maintenance too. Some breakers offer easier access for testing or replacing components. Think carefully about these details to avoid costly mistakes later.

Comparison of Leading Molded Case Circuit Breaker Brands in 2026

When choosing a molded case circuit breaker, understanding the leading brands is essential. Different manufacturers offer various features. Some focus on increased safety, while others prioritize durability. It can be overwhelming. The options seem endless. Each brand has its unique design philosophy, which influences performance.

Features like breaking capacity and thermal settings are crucial in making a choice. Some brands excel in this area, providing customizable options. However, not every product lives up to the hype. Some models may have reliability issues that are not apparent at first glance. It's important to research and consider user reviews. Look for feedback on longevity and real-world performance.

Comparing these brands can reveal discrepancies. Certain brands tend to excel in cost-effectiveness, while others might fall short. Additionally, the availability of customer support can vary greatly. It’s worth contemplating how these factors impact your decision. Investing time in a thorough comparison could save future headaches. In the end, the right choice should balance both functionality and dependability.

2026 Best Molded Case Circuit Breaker Reviews and Buying Guide

| Model | Current Rating (A) | Voltage Rating (V) | Breaking Capacity (kA) | Trip Type | Price (USD) |

|---|---|---|---|---|---|

| Model A | 100 | 480 | 65 | Thermal/Magnetic | 120 |

| Model B | 150 | 600 | 78 | Electronic | 145 |

| Model C | 200 | 690 | 85 | Thermal/Magnetic | 200 |

| Model D | 300 | 720 | 95 | Electronic | 280 |

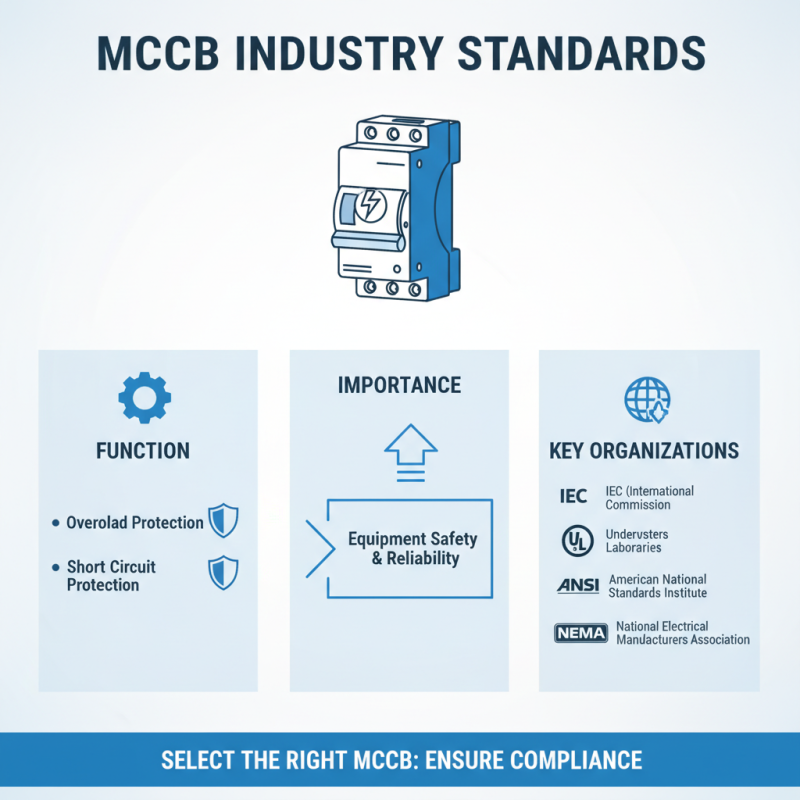

Industry Standards and Ratings for Molded Case Circuit Breakers

Molded case circuit breakers (MCCBs) play a crucial role in electrical systems. They protect equipment from overloads and short circuits. Understanding industry standards is essential for selecting the right MCCB. Various organizations set these standards, influencing design and performance.

The National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL) are key players. They establish guidelines for safety and efficiency. When choosing an MCCB, check if it meets these standards. Ratings like current interrupting capacity (ICC) matter. Higher ICC ratings ensure greater protection in critical applications. Inspect the thermal magnetic trip settings too; they vary widely across models.

Keep in mind that not all MCCBs are created equal. Some may not meet the required standards, despite looking similar. It's easy to overlook details, but doing so can lead to issues. Poor choices can result in equipment damage or safety risks. Research and compare options carefully. Also, consider installation environments, as they affect performance. Choosing the right MCCB might feel overwhelming, but it’s necessary for long-term reliability.

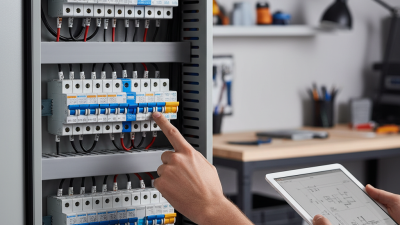

Maintenance and Troubleshooting Tips for Molded Case Circuit Breakers

Molded case circuit breakers (MCCBs) serve as essential devices in electrical systems. Regular maintenance ensures reliability and safety. According to a recent industry report, improper handling or neglect can lead to a 30% increase in device failure rates. Therefore, understanding troubleshooting techniques can save time and costs.

Inspecting connections regularly is vital. Loose connections can cause overheating. This heating may lead to tripping, resulting in downtime. Tightening connections can improve performance. Additionally, checking the internal mechanisms at least twice a year is a good practice. This ensures smooth operation and identifies any wear.

Another critical aspect is load monitoring. Keeping track of the load allows for early detection of overloads. Studies show that devices running above their rated capacity can shorten lifespan by 50%. Many users overlook this detail, leading to unexpected failures. Recorded data on operational trends can aid in making informed decisions. Emphasizing preventative measures can enhance device longevity. This approach requires a proactive mindset.

Related Posts

-

Understanding Circuit Breaker Switch Types and Their Applications

-

10 Essential Tips for Choosing the Right Circuit Breaker Switch

-

How to Reset a Home Circuit Breaker Troubleshoot Common Issues

-

7 Essential Tips for Choosing the Right Air Circuit Breaker for Your Electrical Systems

-

What is a Miniature Circuit Breaker and How Does it Work in Electrical Systems

-

Top 10 Air Circuit Breakers: Best Options for Your Electrical Needs