2025 Top Soft Starter Technologies for Efficient Motor Control

In the ever-evolving landscape of industrial motor control, the significance of soft starters cannot be overstated. These devices are essential for managing the inrush current and providing a smooth start-up for various types of electric motors. According to Dr. Emily Carter, a noted expert in the field of motor control technologies, “Soft starters are the unsung heroes of efficient motor management, crucial for reducing wear and tear on machinery while enhancing operational efficiency.”

As industries face increasing demands for energy efficiency and reduced maintenance costs, the adoption of innovative soft starter technologies becomes paramount. By employing state-of-the-art designs and functionalities, these devices not only extend the life of motors but also contribute significantly to energy savings. The developments leading up to 2025 are set to redefine how industries implement soft starters, driving advancements that align with sustainability goals.

This exploration of the top soft starter technologies for 2025 highlights the critical role they play in modern motor control applications. As we dive into the upcoming trends and innovations, it becomes clear that the future of soft starters is bright, providing solutions that meet the challenges of today while paving the way for more efficient motor management tomorrow.

Overview of Soft Starter Technologies in Motor Control

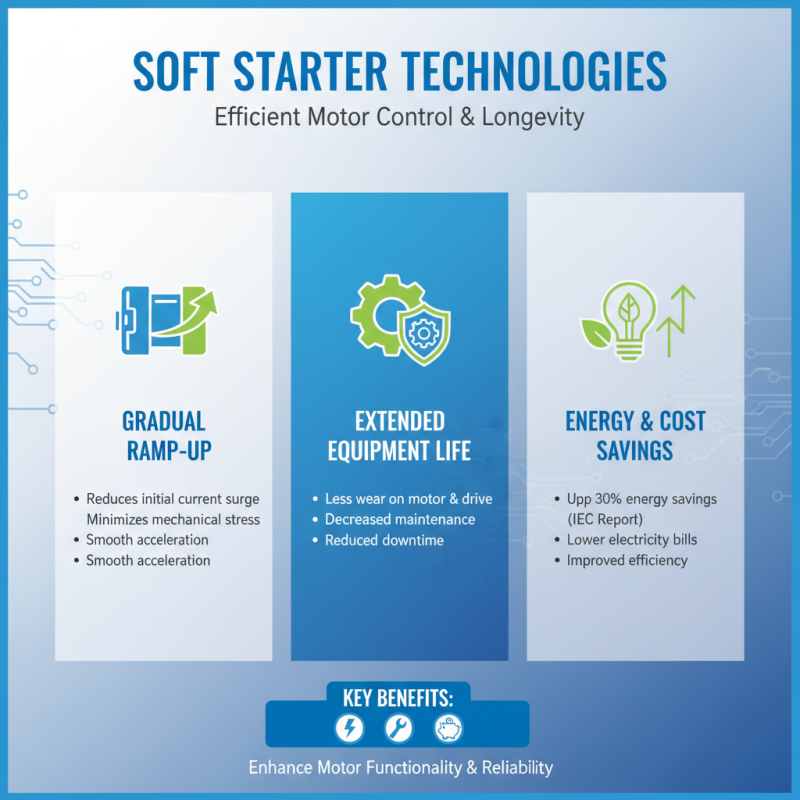

Soft starter technologies play a crucial role in the efficient control of electric motors, offering a range of benefits that enhance the functionality and longevity of motor applications. By allowing for a gradual reduction in the voltage supplied to the motor, soft starters minimize the initial surge of current that typically occurs when a motor is switched on. According to a report by the International Electrotechnical Commission (IEC), implementing soft starters can lead to energy savings of up to 30% by reducing mechanical stress and wear on motors and drive systems.

One significant advantage of soft starters is their ability to improve overall system reliability. By controlling the starting current and preventing abrupt mechanical forces, these technologies reduce the risk of equipment damage, thus ensuring operational stability. A recent study from the Electric Power Research Institute (EPRI) highlights that industries implementing soft starter solutions have noted a 25% reduction in maintenance costs over a five-year period, attributing this to fewer motor failures and less frequent replacements.

Tips: When selecting a soft starter, consider not only the power rating but also the compatibility with your existing motor systems. Additionally, look for features such as built-in protection mechanisms against overloads and phase loss, which can further enhance operational efficiency. Regularly reviewing these aspects can lead to significant long-term savings and improved performance in your motor applications.

Key Features and Benefits of Modern Soft Starters

Modern soft starters have become essential components in efficient motor control systems, offering a range of key features designed to optimize performance. One of the primary benefits of these devices is their ability to reduce the inrush current at motor startup. By gradually ramping up the voltage, soft starters minimize mechanical stress on both the motor and connected equipment, which significantly extends lifespan and reduces maintenance costs. This controlled starting process not only helps in preventing damage but also lowers energy consumption during startup.

Additionally, many contemporary soft starters come equipped with advanced control algorithms that provide enhanced operational flexibility. These systems often include features such as adjustable start and stop times, as well as customizable acceleration and deceleration profiles. Such capabilities allow for precise control over motor behavior tailored to specific applications, leading to improved process efficiency and productivity. Furthermore, integrated protection features, such as overload and phase loss protection, ensure the safety of both the motor and the overall system, making modern soft starters an invaluable asset in various industrial settings.

Comparison of Traditional and Advanced Soft Starter Solutions

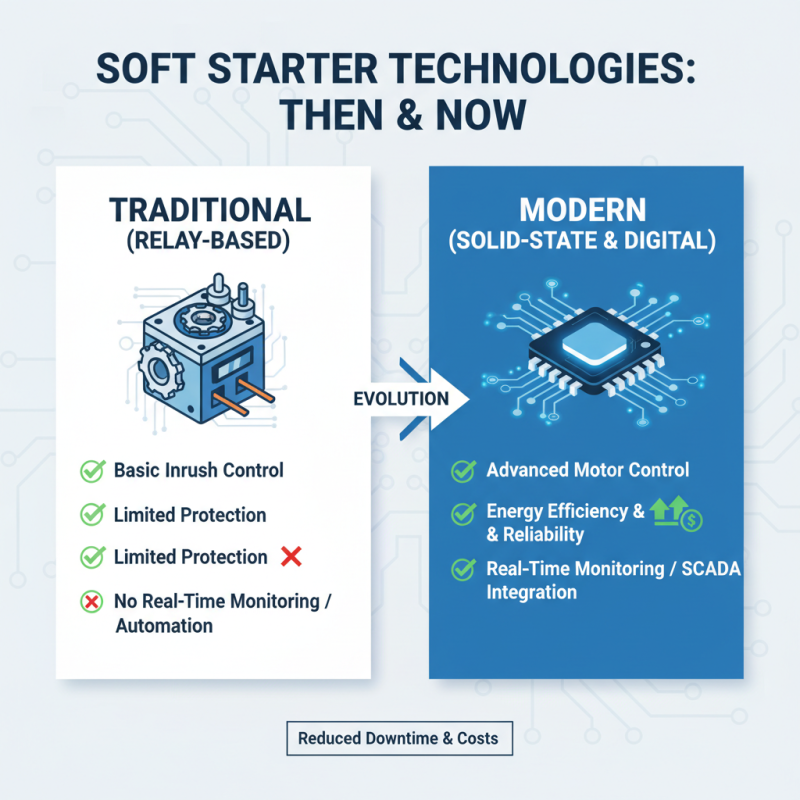

The evolution of soft starter technologies has introduced significant advancements in motor control efficiency. Traditional soft starters primarily rely on relay-based systems to manage the inrush current during motor startup. While these systems provide basic control and protection, they often lack the sophistication needed for modern applications, particularly in environments where energy efficiency and operational reliability are critical. Moreover, traditional solutions may not support advanced features like real-time monitoring or integration with automation systems, leading to potential inefficiencies and increased maintenance costs.

In contrast, advanced soft starter solutions leverage cutting-edge technology to enhance both performance and adaptability. These systems utilize microprocessor-based controls, allowing for precise control over motor starting and stopping sequences. Features such as programmable ramp-up and ramp-down times, fault diagnostics, and communication capabilities enable seamless integration into smart grid systems. This not only results in reduced mechanical stress on the motor and connected machinery but also contributes to significant energy savings over time. As industries strive for greater efficiency and sustainability, the shift towards advanced soft starters is becoming increasingly evident, marking a pivotal transition in motor control strategies.

Emerging Trends in Soft Starter Technologies for 2025

As industries evolve, soft starter technologies are becoming increasingly sophisticated, aligning with the demands for enhanced efficiency and sustainability in motor control. In 2025, key trends indicate a shift towards more intelligent and automated soft starters, integrating advanced algorithms and machine learning capabilities. These innovations aim to optimize motor performance by analyzing operational conditions in real time, which allows for smoother starts and reduced energy consumption.

Additionally, the rise of IoT (Internet of Things) connectivity is revolutionizing the way soft starters function. By integrating IoT capabilities, these devices can communicate with other machinery and systems, enabling predictive maintenance and performance monitoring. This trend not only enhances operational efficiency but also minimizes downtime, contributing to overall productivity. Moreover, the incorporation of energy harvesting technologies is expected to play a significant role, allowing soft starters to utilize energy generated during motor startup for monitoring systems, thereby further improving energy efficiency and sustainability within industrial operations.

Impact of Soft Starters on Energy Efficiency and Performance

Soft starters play a crucial role in enhancing the energy efficiency and overall performance of motors in various applications. By gradually ramping up the voltage and current supplied to the motor, these devices significantly reduce the inrush current that typically occurs during a motor's start-up phase. This controlled startup not only minimizes electrical stress on the motor and associated equipment but also results in lower energy consumption. Consequently, businesses can achieve notable reductions in their energy costs while extending the lifespan of their motor systems.

Moreover, the impact of soft starters on motor performance goes beyond energy savings. By preventing mechanical shocks associated with abrupt starts, they help maintain the integrity of connected machinery and reduce wear and tear. This improved performance is particularly beneficial in industrial settings, where consistent operation is critical for productivity. Additionally, the enhanced control offered by soft starters allows for smoother operations, which not only promotes better efficiency but also supports the effective integration of motors into automated systems, paving the way for more intelligent and responsive manufacturing processes.

2025 Top Soft Starter Technologies for Efficient Motor Control

| Technology Type | Efficiency Improvement (%) | Impact on Performance | Typical Applications |

|---|---|---|---|

| Digital Soft Starters | 20-30% | Smooth Start/Stop, Reduced Mechanical Stress | Pumps, Fans, Conveyors |

| Phase-Control Soft Starters | 15-25% | Minimized Inrush Current, Enhanced Control | Compressors, HVAC Systems |

| Bypass Contactor Soft Starters | 10-20% | Reduced Energy Consumption in Running Mode | Industrial Machinery, Large Motor Applications |

| Integrated Drive Soft Starters | 25-35% | Comprehensive Control, Energy Saving | Fan and Pump Systems |

| Adaptive Soft Starters | 20-40% | Real-time Optimization of Startup Conditions | Variable Load Applications |

Related Posts

-

Top 10 Benefits of Using Soft Starters in Industrial Applications

-

Understanding the Importance of DC Switches in Modern Electrical Systems

-

Exploring Innovations in Molded Case Breakers at the 138th Canton Fair 2025: Industry Trends and Insights

-

Understanding the Impact of DC Switches on Renewable Energy Systems Efficiency

-

2025 Top Surge Protection Circuit Breaker: Your Essential Buying Guide

-

Understanding the Importance of MCCB Breakers in Modern Electrical Systems